The first of Coperion’s new generation of Polymer Pellet Railcar Loading Stations have been successfully commissioned at a new HDPE production facility in La Porte, Texas/USA.

Coperion and Muhr, Brannenburg/Germany have formed a cooperation agreement in November 2014 and have developed a loading technology that optimizes both loading performance and the loading process providing best in the business railcar filling rates and efficiencies.

The customer’s loadout concept fully utilises the capabilities of Coperion/Muhr’s loading technology enabling maximum filling efficiency for all railcars potentially saving up to 1,000 railcar deliveries per year by loading 15-20% more product in each car than with previous generation distributers and conventional operating models.

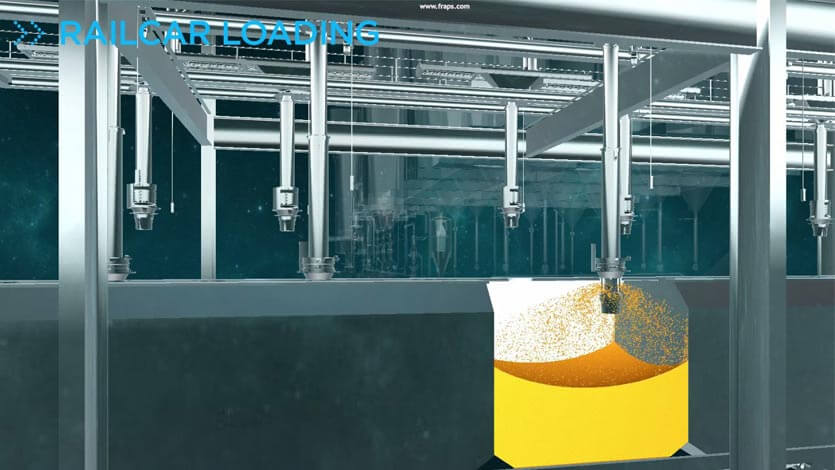

The system comprises four loading bays that provide instantaneous filling rates of up to 400 t/h (882,000 lbs/h) and railcar filling efficiencies of ≥ 95% either by weight or volume (depending on the railcar size and product bulk density being loaded). Once set up for loading the railcar is filled within 20 minutes supporting the minimization of the time required for the whole railcar loading operation.

Since 2014 Coperion and Muhr have supplied a total of 11 railcar loading stations serving five new grass root Polyolefin production plants with a total annual production of ~1.3 mio. tonnes (2.86 billion lbs). Each loading station comprises individually designed conveying and gravity loading systems serving four telescopic loaders with the unique high efficiency radial distributor (spreader).

Intensive tests before launch

To verify performance and optimize the loading process Coperion and Muhr carried out intensive tests at Coperion’s test center in Weingarten, Germany, with the radial distributer utilising a 1:1 wooden box model of a typical railcar chamber. The back wall of the box could be moved to simulate outer or inner railcar chambers. The test results not only confirmed the high throughput but also the excellent filling efficiency achievable with the distributor.