Moves bulk material short distances to one destination

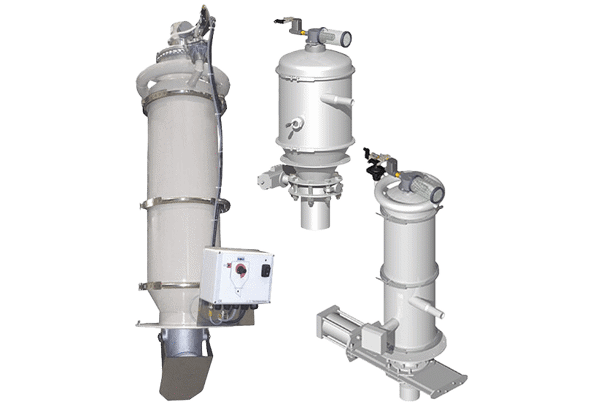

Coperion K-Tron vacuum loaders are designed to high quality standards for pneumatically conveying powders, pellets and granular materials for the bulk material handling industries.

Our loaders are available in powder and pellet versions, as self-contained units or venturi style that utilized compressed air to create a vacuum convey source.

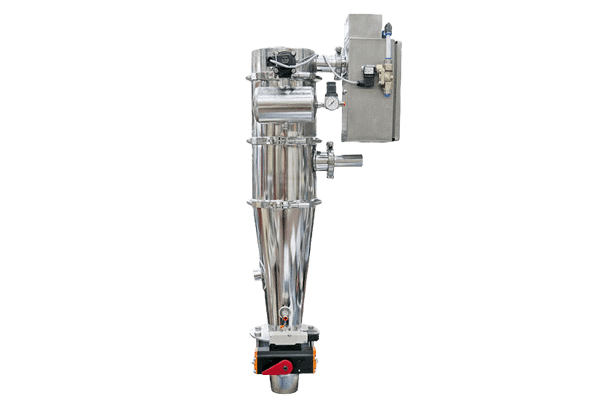

P-Series venturi loaders are often used for loading hoppers as well as loss-in-weight feeder refill. They are designed to convey powders and friable materials for sanitary, pharmaceutical, food and chemical applications.