Technology solutions for any cable recipe

Quality is our benchmark. This is the way for you to get exactly what you expect for the processing of cable compounds: a compounding system that achieves the highest product quality and maximum economic efficiency.

Coperion specializes in the design and implementation of complete systems to produce cable compounds.

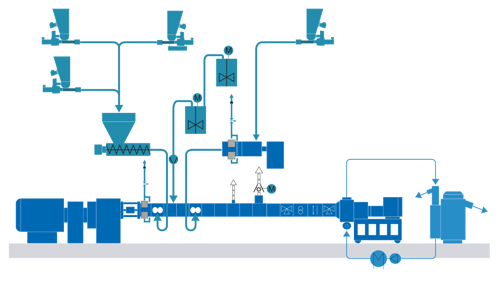

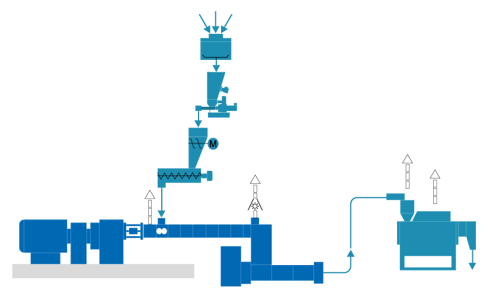

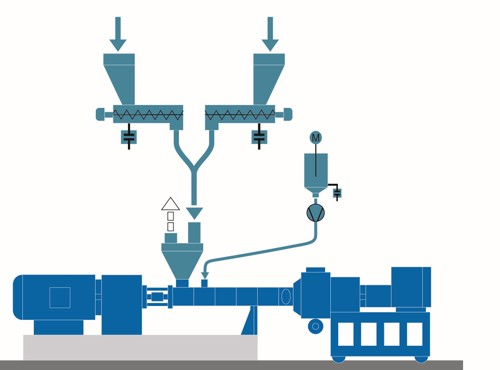

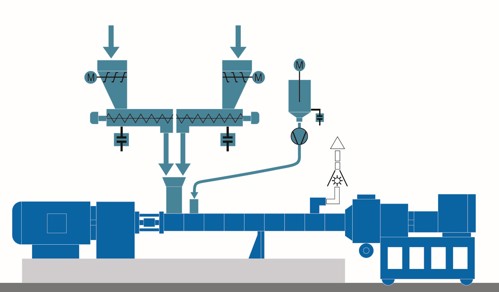

Our technologies have long proven themselves in the compounding of a wide variety of cable applications. We realize solutions for all production steps – from material handling and feeding, to dryblend production, compounding, and pellet cooling, to storage and filling.