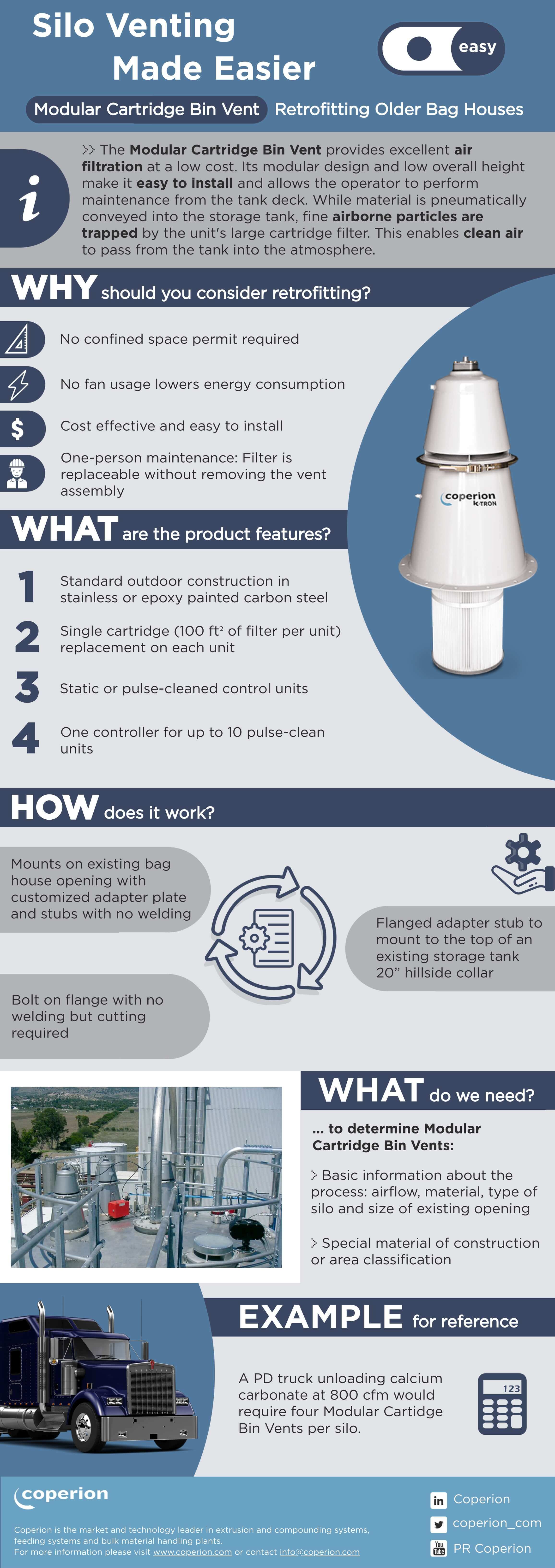

Why should you consider retrofitting your silo venting system and when is the Modular Cartridge Bin Vent the right solution for you? Coperion K-Tron recommends the system if you wish to improve your operational safety while not having the resources for time-consuming and costly maintenance. To access Coperion K-Tron’s silo vents you are not required to have a confined space permit. Its operation is known for being energy efficient as, unlike other bin vents, the Modular Cartridge Bin Vent does not include any exhaust fans. Therefore, the upgrade will have a lasting impact on your energy bills. The solution is easy to install and comes in a well-conceived structure. Design features such as the quick-release clamps allow for comfortable cleaning. Additionally, only one person is required for maintaining the equipment as the filter is replaceable without removing the vent assembly.

The Modular Cartridge Bin Vent is suitable for standard outdoor constructions and comes in stainless or epoxy painted carbon steel. Each Modular Bin Vent comes with a single cartridge filter with 100 ft2 of filter media. This filter cartridge is accessible without entry into a bag house. The Modular Bin Vent is available in static or in a pulse clean version where reverse jet cleaning from a compressed air accumulator pulses the cartridge filter. As a result, any fines are dislodged and returned to the storage tank. It is possible to use one controller for up to 10 pulse clean units making the system easy to manage.

How does equipping your silos with the Modular Cartridge Bin Vent work? Thanks to its flanged adapter stubs the system can be easily mounted on existing bag houses. There are different ways to mount the MCBV. The first would be an adapter to an existing 20” stub flange. The second would be a bolted plate from the existing bag house flange to the MCBV flange. Lastly a new flange could be cut and welded onto the top of the silo. To determine the right Modular Cartridge Bin Vent for you, our experts require basic information about your process such as airflow, material, type of silos as well as the size of the existing opening. In addition, we need to take special construction materials or area classification into account. The number of units depends on the capacity of your product. The following example represents a rough estimate: A PD truck unloading calcium carbonate at 800 cfm would require four Modular Cartridge Bin Vents per silo.