Reliable feeding of most bulk materials

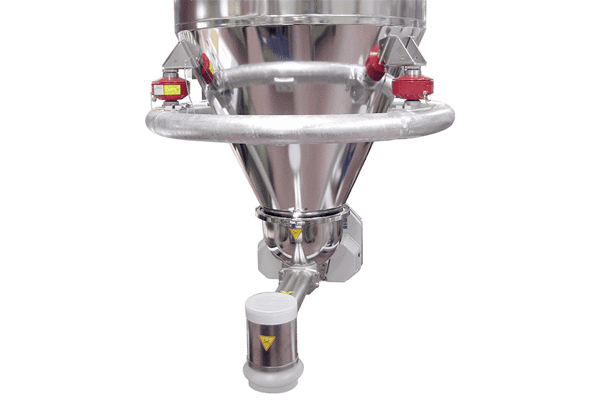

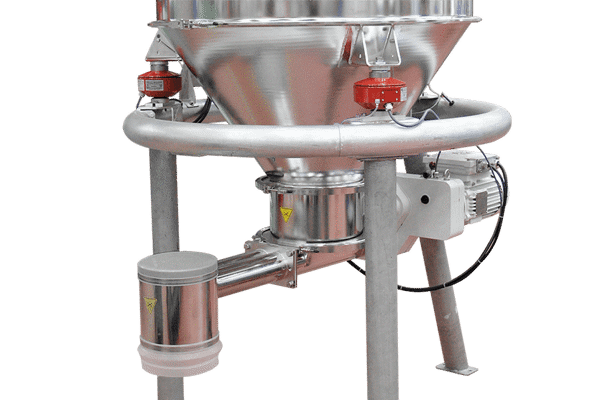

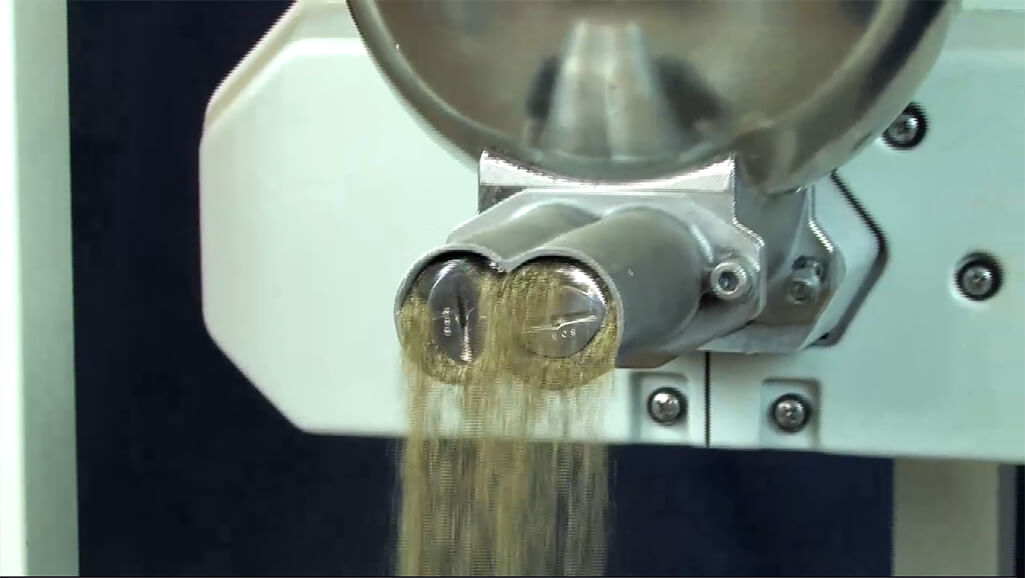

Twin screw feeders can be used for free flowing powders and fine granulates but they are ideal for feeding difficult materials such as pigments, sticky, bridging or flooding powders, fiber and fiberglass.

Screw feeders are the most common and economical volumetric feeders you can buy. Coperion K-Tron makes both single screw and twin screw volumetric feeders in a wide range of sizes to meet your feed rate requirements and solve your material handling problems. Some are optimized for quick material changes and can even be configured for differing material properties. Others feature easy cleanability and meet food and pharmaceutical sanitary requirements.