Compounding

Coperion at K 2025: Technologies for Greater Compounding Efficiency

At K 2025 in Dusseldorf (8-15 October 2025) at Booth 14B19 in Hall 14, Coperion is presenting its trailblazing technologies for high-efficiency plastics compounding. Increasing efficiency is the key to economical and sustainable success in plastics processing. Appropriate to the occasion, Coperion will present new products and developments for various process steps that contribute to increases in both compound quality and machine efficiency. Moreover, they further advance responsible use of resources. Along with compounding, technologies for plastics recycling constitute a Coperion core competency.

C-Beyond

Masterbatch Manufacturer cpc Increases Operational Efficiency of its Coperion ZSK Extruders Using C-BEYOND

To ensure maximum efficiency of both its extruders and the entire production process in the long run, masterbatch manufacturer colorplasticchemie Albert Schleberger GmbH (cpc) in Remscheid Germany has enhanced its ZSK twin screw extruders with the Coperion C-BEYOND digital platform. This system records all the operational parameters of every ZSK extruder at cpc in a cloud, available in real time for valuable analysis.

Plastics Recycling

Coperion at K 2025: Innovative Interplay of Plastics Recycling Technologies

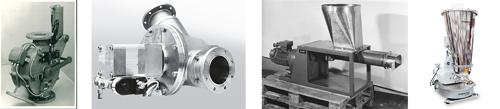

At Booth 9B34 in Hall 9, the focus will be on Herbold Meckesheim’s technologies for mechanical processing of plastics waste. On display will be the new T 150-300 Mechanical Dryer and the SMS 80-200 Granulator. In the Open Area, Pavilion FG/CE07, visitors can witness the seamless interplay of all Coperion recycling technologies. On view will be a Herbold Meckesheim Hydrocyclone Stage, the ZSK FilCo filtration compounder, the ZS-B MEGAfeed side feeder, a Coperion K-Tron K3-V200 vibratory feeder, an S60 single screw feeder and the MechaTron® flat bottom feeder. Also on display will be a mobile deodorization unit for reliably removing unpleasant odors from recyclates. In addition to plastics recycling, Coperion specializes in plastic compounding technologies. These core competencies will be on display at Booth 14B19 in Hall 14.

Herbold Meckesheim

Herbold Meckesheim Unveils Cutting-Edge Recycling Solutions at K 2025

Meckesheim, Germany, July 2025 – Herbold Meckesheim, a brand of Coperion, will showcase its latest advancements in plastics recycling technology at K 2025, taking place from October 8 to 15 in Dusseldorf, Germany. Building on its long-standing expertise in modular system solutions for size reduction, washing, separation, drying, and agglomeration of plastics waste, Herbold Meckesheim offers tailored, highly automated plants for numerous industrial recycling applications. The company will present a range of integrated systems and solutions designed for mechanical processing, including the new high-capacity Mechanical Dryer T150-300 and the latest SMS granulator model. Visitors can explore these innovations firsthand at Hall 9, Booth 9B34. In addition, a Hydrocyclone Separation Stage will be showcased in the Coperion and Herbold Meckesheim Recycling Pavilion in the Open Area FG/CE07, where the companies will demonstrate their comprehensive interlocking recycling solutions.

Twin Screw Extruders

Coperion at K 2025: ZSK and STS Twin Screw Extruders: More Efficiency in Compounding and Recycling

Stuttgart, September 2025 – The central focus of Coperion's research and development work in the field of twin screw extrusion is increasing efficiency. Paths to greater efficiency in compounding and recycling will also be the focus of Coperion's appearance at K 2025. At Booth 14B19 in Hall 14, Coperion will exhibit a ZSK 58 Mc18 twin screw extruder. This model, with a 58 mm screw diameter, achieves throughputs of up to 2,500 kg/h with low energy consumption and a high degree of automation. Additionally, Coperion will display an STS 35 Mc11 twin screw extruder at the same booth; this model has been specially optimized for masterbatch manufacturing. At the Recycling Pavilion FG/CE07 in the Open Area, Coperion will exhibit the added value of its twin screw extruders for recycling plastics. Coperion’s patent-pending ZSK FilCo filtration compounder will be on view there.

Feeding

Coperion at K 2025: Driving Innovation Across the Plastics Industry with Extended Range of Technologies for High-Accuracy Feeding and Weighing

Niederlenz, Switzerland, September 2025 – Coperion will unveil its enhanced portfolio of smart feeding and weighing technologies at K 2025, highlighting the integration of two industry-leading technology brands – Coperion K-Tron and Coperion (formerly Schenck Process FPM) and its AccuRate® and MechaTron® feeding lines. This merger consolidates a comprehensive array of solutions for the plastics industry, providing manufacturers with unparalleled options for feeding and weighing technologies.

Material Handling

Celebrating 280 Years of Material Handling Leadership

Stuttgart, September 2025 – The company’s material handling business in Weingarten, Germany, and its feeder and conveying manufacturing facility in Niederlenz, Switzerland, both reach an impressive 125 years of operation, while Coperion Ideal in Noida, India, marks its 30th anniversary. Together, these milestones total an extraordinary 280 years of combined experience, know-how, and dedication to advancing the industry.

Twin Screw Extruder

NexKemia Expands EPS Production Capabilities with ZSK Twin Screw Extruders to Incorporate Recyclates

Stuttgart, October 2025 – NexKemia Petrochemicals Inc., a leading firm in manufacturing expandable polystyrene (EPS), has relied on ZSK twin screw extruders from Coperion since 2020. Focusing on innovative manufacturing processes and sustainability, NexKemia provides products for the packaging industry and as well as for building insulation. Along with white EPS, NexKemia also produces EPS mixed with graphite, known as GPS (polystyrene mixed with graphite-enhanced polystyrene), as well as products containing up to 30% recyclate. For manufacturing and product development, NexKemia uses Coperion ZSK twin screw extruders, which enable an environmentally friendly production and gentle product handling of white and gray EPS as well as the integration of recycled materials on a single production line.

Direct Compounding

EPC and Coperion Present Innovative Direct Compounding Technology for Cost-Efficient Polycarbonate Production

EPC Engineering & Technologies GmbH from Arnstadt, in close cooperation with Coperion GmbH from Stuttgart, have developed a groundbreaking one-step process for the direct compounding of polycarbonate (PC) melt. This new technology offers a highly flexible and cost-efficient solution for the production of high-quality PC products using non-phosgene polymerization.

Recycling

Magpet commissions Herbold Meckesheim with another PET bottle washing line

Indian preform and plastic packaging manufacturer Magpet Polymer Pvt Ltd has commissioned Herbold Meckesheim with another PET bottle washing line.

The new washing line is an extension of the bottle-to-bottle recycling plant that Coperion and Herbold Meckesheim are currently installing for Magpet in India. The granulators and an initial washing line have already successfully commenced operation. With the new washing line, Magpet will be able to increase its PET washing capacity by a factor of 2 to 2.5.

K 2025

Open navigation

K 2025

Open navigation