Recycled plastics require deodorization at several points along the recycling process chain. Only in this manner can one be certain that the recyclate will meet very high mechanical and sensory demands, will not exhibit undesired odors, and will achieve the quality needed for the intended application.

Coperion and Herbold Meckesheim offer a variety of solutions all along the recycling process to remove unpleasant odors from plastic. These technologies excel due to their especially reliable and energy-efficient operation.

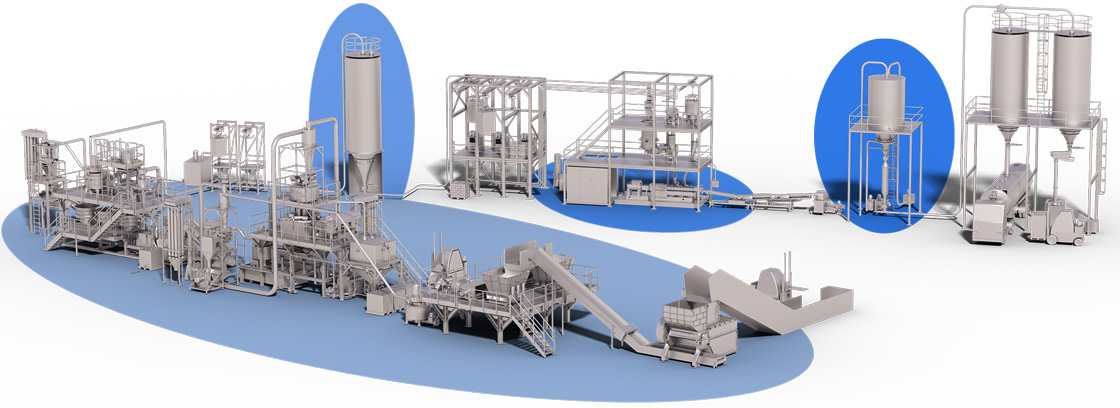

In a first step, odors are eliminated as the waste plastic undergoes mechanical pretreatment during shredding, washing and drying. Further odors can be removed from the shredded plastic in a silo using fresh air circulation.

The next, intensive devolatilization step, which markedly improves the recompound’s sensory quality, takes place during compounding in a ZSK twin screw extruder. Following melting and intensive homogenization of the waste plastic in the ZSK extruder’s process section, volatile particles are degassed from the plastic melt in a highly energy efficient process. Using various technologies such vacuum devolatilizations, these dissolved gases are reliably removed from the product. This effect can be significantly intensified with the addition of liquid stripping agents. Use of a ZS-EG side devolatilization unit provides a particularly effective and stable degassing process in the ZSK twin screw extruder, maximizing its deodorizing capabilities when high quantities of gas are present.