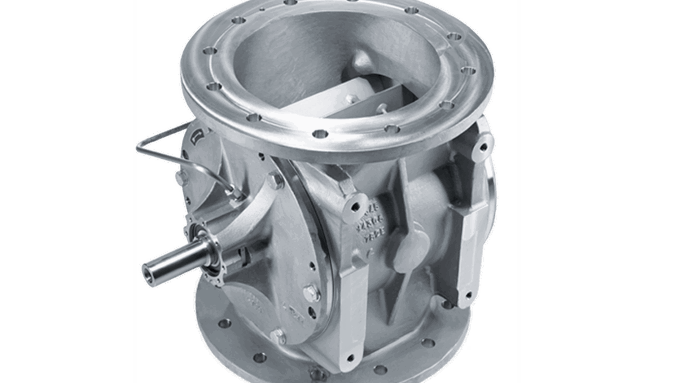

Rotary and diverter valves play a vital role when it comes to optimizing material flows in plastics and chemical processing. They ensure efficient handling of all sorts of bulk solids throughout the entire production - from pellets to powders. At the same time, both the plastics and the chemical industry pose unique challenges, including high temperatures, abrasive materials as well as the need for precise control and minimal downtime due to cost pressure. The design of these valves must accommodate all these requirements while enhencing durability and facilitating easy maintenance for uninterrupted production and thus reduced operational costs. By using robust materials, integrating advanced engineering and innovative solutions with the operators in mind, Coperion rotary and diverter valves have proven themselves in these harsh conditions. Decades of experiences with more than 15,000 different bulk materials and our know-how acquired through the design as well as installation of plants in the plastics industry, allow us to give the right recommendations for your process. Thanks to our comprehensive portfolio which goes beyond rotary and diverter vales as well as our holistic view, we are able to offer powerful components for every process stage.

Optimizing Efficiency with Advanced and Reliable Solutions

Durable Components for Demanding Chemical Applications

Driven to support plastics and chemical producers achieve efficient, high-performance processing

Expertise in Every Component, Strength in Every System

Coperion’s Integrated Solutions for the Plastics Processing Industry

Coperion’s comprehensive process know-how in the plastics industry enables us to take a holistic view of your operation. We don’t see components as isolated units, but as integrated parts of a complete system. Because we also provide solutions for the entire process, we’re able to offer well-rounded, system-level advice. Our customers benefit from working with experts who understand the bigger picture and discuss their challenges at eye level.

TALK TO EXPERTTypical Applications of Coperion Valves in Plastics and Chemicals

- Polyolefins

- Engineering Plastics

- Compounding & Processing

- Plastics Recycling

- Chemicals and Batteries

The production of polyolefins, such as polyethylene and polypropylene, involves the precise handling of powders and granules to create high-performance plastics that are ultimately used for different products. Rotary and diverter valves are essential components in this process, ensuring controlled, reliable flow of materials between reactors, dryers, and storage systems. Rotary valves provide consistent metering and airtight sealing, preventing contamination and material loss. Diverter valves enable the flexible routing of resins to different processing or packaging lines without interrupting operations.

When it comes to the production of engineering plastics (e.g. polyamide, polycarbonate or PEEK) for a variety of end uses, precise handling of often sensitive materials is required. Rotary and diverter valves are crucial in ensuring contamination-free transfer throughout the different stages including compounding, drying, and conveying stages. While rotary valves deliver consistent flow control of additives and reinforcing agents, diverter valves allow seamless switching between process lines.

In plastics compounding, polymers are blended with additives, fillers and colorants to achieve the desired end results. Precise and efficient material handling plays a key role in plastics processing which includes the installation of rotary and diverter valves. They not only ensure a consistent flow, but also accurate feeding of powders, pellets, and liquids throughout the process. Rotary valves support uniform feeding into extruders and mixers, while maintaining system pressure and preventing leaks. Diverter valves enable flexible routing of materials between lines, reducing downtime and cross-contamination.

Plastics recycling involves handling a wide range of materials. This varies from shredded waste (mostly in the form of flakes or fibres) and finally reprocessed pellets. In some steps of the recycling process, rotary and diverter valves can contribute to a consistent flow and preventing contamination throughout sorting, washing, drying, and reprocessing. Rotary valves ensure reliable material control from one process step to another. Diverter valves provide flexible routing between recycling steps, allowing efficient switching between material streams.

Chemical manufacturing and battery material production both involve the precise handling of powders, granules, and liquids under strict safety, purity, and contamination-control standards. Rotary and diverter valves are critical for controlling material flow in processes such as mixing, reaction, drying, and packaging. Rotary valves ensure accurate, consistent feeding while preventing leaks and contamination, while diverter valves enable safe, flexible routing of materials between process lines or storage systems.

Critical Considerations in Plastics and Chemicals Applications

Plastics processing as well as chemical environments are some of the most demanding in manufacturing – combining abrasive materials, high temperatures, and continuous operation requirements. To stay competitive, you need solutions that are not only powerful and robust enough to handle these harsh conditions but also economical, maximizing uptime while minimizing total cost of ownership. How do we address these challenges? Here are some of the answers to the most common customer questions.

-

Will the valve materials withstand the abrasiveness, stickiness, or corrosiveness of my specific plastics or additives?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

-

What is the expected lifespan of the valve components in harsh environments?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

-

How easy is it to access, clean, and maintain the valves, especially if I work with sticky or reactive materials?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

-

How does the valve minimize leakage, cross-contamination, or product loss?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Want to Discuss Your Individual Challenge?

Get in Touch with Us!

Coperion has experience with various applications in the plastics industry. With our innovative solutions and a variety of customization options, we are confident to find the right components for your needs.

Contact usFind the Right Coperion Valve for Your Application

Rotary Valves

Explore our comprehensive range of rotary valves designed for optimal performance and reliability.

Diverter Valves

Discover our extensive selection of diverter valves engineered for superior performance and versatility in diverse applications.

High-class Components

Open navigation

High-class Components

Open navigation