Coperion received a technologically interesting order for retrofitting an existing plant with the new conveying technology FLUIDLIFT ecoblue®. In this plant, the customer produces approx. 400 kta of LDPE.

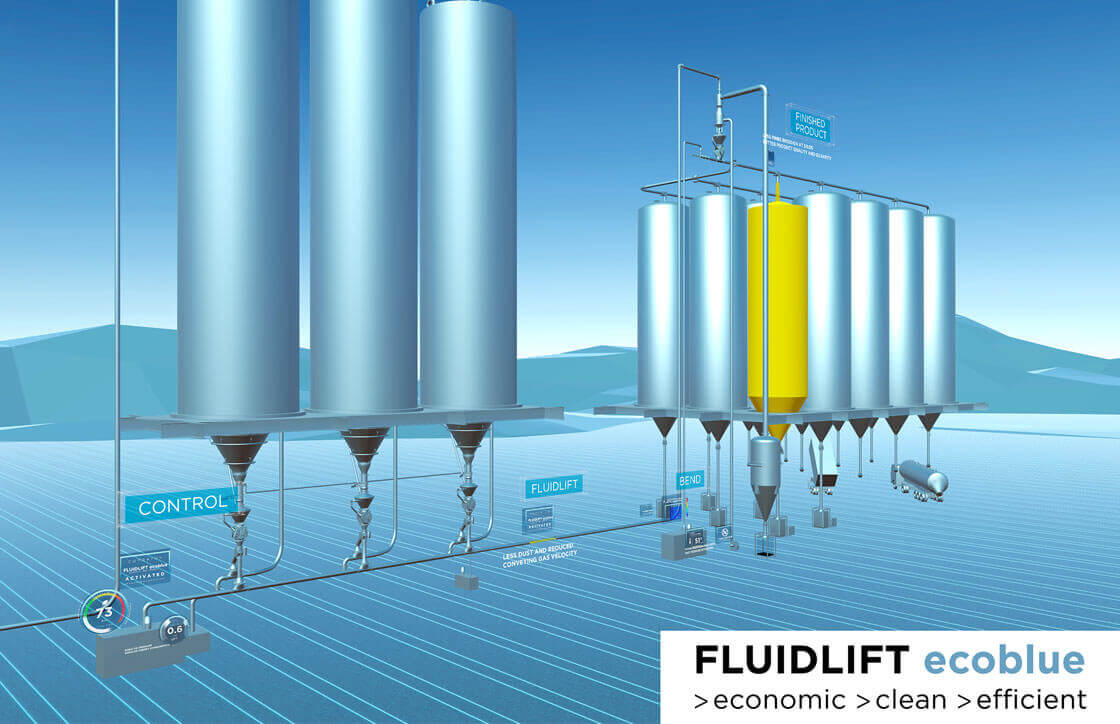

Coperion's highly innovative FLUIDLIFT ecoblue® is a pneumatic conveying technology which enhances process quality and efficiency, especially for polyolefin pellets. Compared to conventional designs, this technology generates much less dust and streamers, which improves the quality of the product and reduces waste tremendously – by up to 98%.

In this particular case the customer's main target is to reduce the dust and streamers generated with the installed conventional pneumatic conveying system which needs to be separated from the product and disposed. This causes a considerable amount of waste, added cost for disposal and loss of production material.

For plant operators, another important feature is that FLUIDLIFT ecoblue® can be retrofitted in existing production lines. A new pneumatic conveying line is typically equipped with shot-peened pipes to avoid streamers and minimize fines generation. This was also the case at this plant when it was originally erected. Over the years, the shot-peening is subject to wear, hence the piping needs replacement after a certain period of operation. This is a major undertaking and requires additional shut-down time causing production loss. All of this is avoided when using FLUIDLIFT ecoblue® and that convinced the customer to commit to the new technology.