This quality of rotary valves can, among other things, be achieved by a reliable and well proven purge gas design to protect the turning parts of the rotary valve.

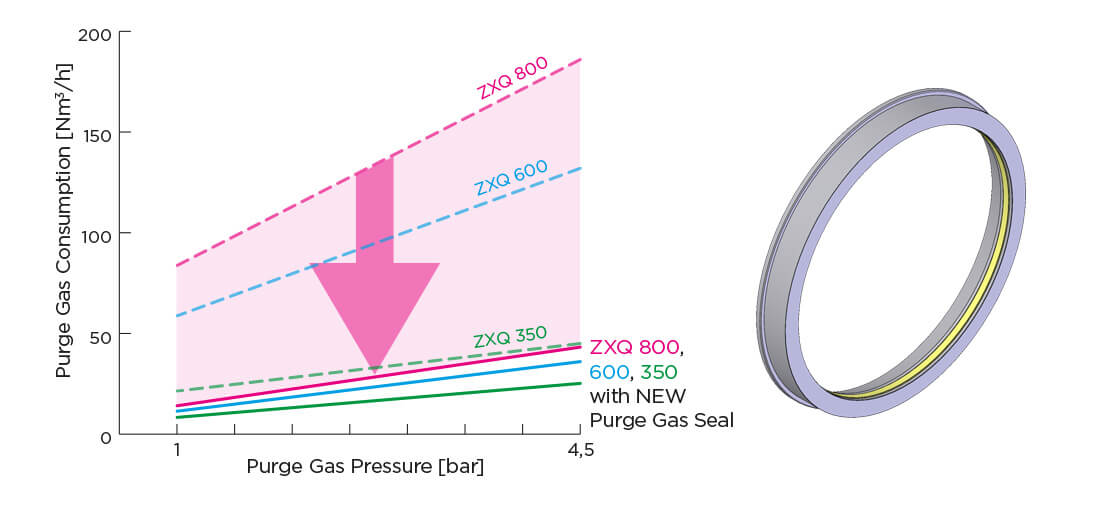

Now, Coperion’s research & development department has further improved the purge gas system, resulting in considerable reduction of the purging gas consumption. This means that savings of up to 70-90% can be achieved (see enclosed graphics).

The innovative design saves energy, will have a payback period within approximately 3 months, depending on the rotary valve size and is designed to also fit into existing equipment.

The high saving potential applies to the installed base as well as to new equipment, contributing to less energy consumption and sustainable operation of the entire system.

The new purge gas system is applicable to various rotary valve models.