Question: The extrusion test lab is equipped with various ingredient feeders and configurations for optimal feeding to the extruder. What other benefits do you see in having the feeding experts on-site?

Cameron Kheradi: The stability of a co-rotating, closely intermeshing twin screw extruder is in many ways reliant on a stable and precise raw material feeding system. Without adequate dosing, the compounding and extrusion process has the potential to become erratic, producing a poor-quality product. As mentioned, in our extrusion test lab we have a variety of highly capable and flexible Coperion K-Tron feeders for feeding powders, pellets, regrind, and flakes. We also have a variety of liquid pumps, equipped with Coperion K-Tron KCM controllers for optimal process control. It is one thing to have the equipment, it is quite another to have the experts and operational know-how under the same roof. Lewis and his team are an invaluable resource to us throughout the process development life cycle. While they provide configuration and feeder selection, recommendations for lab-scale trials, or advising on scale-up considerations, the extruder team can focus their attention on optimizing the extruder configuration and its process parameters.

Question:, How has having the extrusion experts on-site been a benefit for tests being done in the feeding lab?

Lewis Cesarano: Having extrusion experts on-site means there is always someone available to talk with customers about their extrusion applications and the ways Coperion can help them. Together we can consider the requirements for the entire compounding process. We can also take customers on a quick tour through the extrusion lab and show them our additional capabilities. When customers are in for extrusion testing, we extend the same courtesy, whether it be a tour through the feeder lab, discussing feeder testing, or troubleshooting a feeder during the extrusion trial.

Question: Do we have customers taking advantage of having both test centers under one roof? If so, what is the feedback from those customers?

Cameron Kheradi: Many of our customers will leverage both the extruder lab and feeder lab during their process development activities. This can be done actively, by scheduling a stand-alone feeder evaluation as a follow-up or in anticipation of an extrusion trial. Alternatively, an evaluation of bulk materials and feeder selection can also be done in parallel with extrusion testing due to the on-site subject matter experts. Outside of a formal feeder trial, it is not uncommon for Lewis to be present for extrusion tests to observe characteristics and flow behaviors of hard-to-handle materials and make recommendations based on those observations. We value our customer’s time and willingness to conduct trials; it is our goal to make the time spent in the lab as productive and informative as possible. Rather than waiting until after the extruder trial to make feeder recommendations or waiting on the phone with 3rd party vendors for support, we can address issues expediently and effectively by simply taking a two-minute walk down the hall and knocking on Lewis’s door.

Question: Even though every material test has its own set of characteristics have you seen anything recently that stands out in interest?

Lewis Cesarano: It is always interesting going from testing 2,000 kg/h on a K-ML-T80 gravimetric twin screw feeder one week, and then testing less than 100 g/h on a 12 mm twin screw microfeeder the next week!

Cameron Kheradi: All extrusion processes have a strong reliance on feeder capability. However, there are some processes where feed stability and optimization are particularly crucial. The two that come to mind, for different reasons, are reactive extrusion and processing of post-consumer regrind (PCR).

Reactive extrusion is heavily influenced by formulation to achieve not only the desired product properties but also a stable process. Many reactions alter the viscosity or quality of the extrudate. If the viscosity varies due to variations in feed rate, the extrusion process can experience pressure surging or even overreaction or curing of product within the process section or die head. Coperion K-Tron feeders provide the level of precision needed to ensure that reagents are consistently fed at the desired quantities to ensure stable operation and the desired extent of reaction.

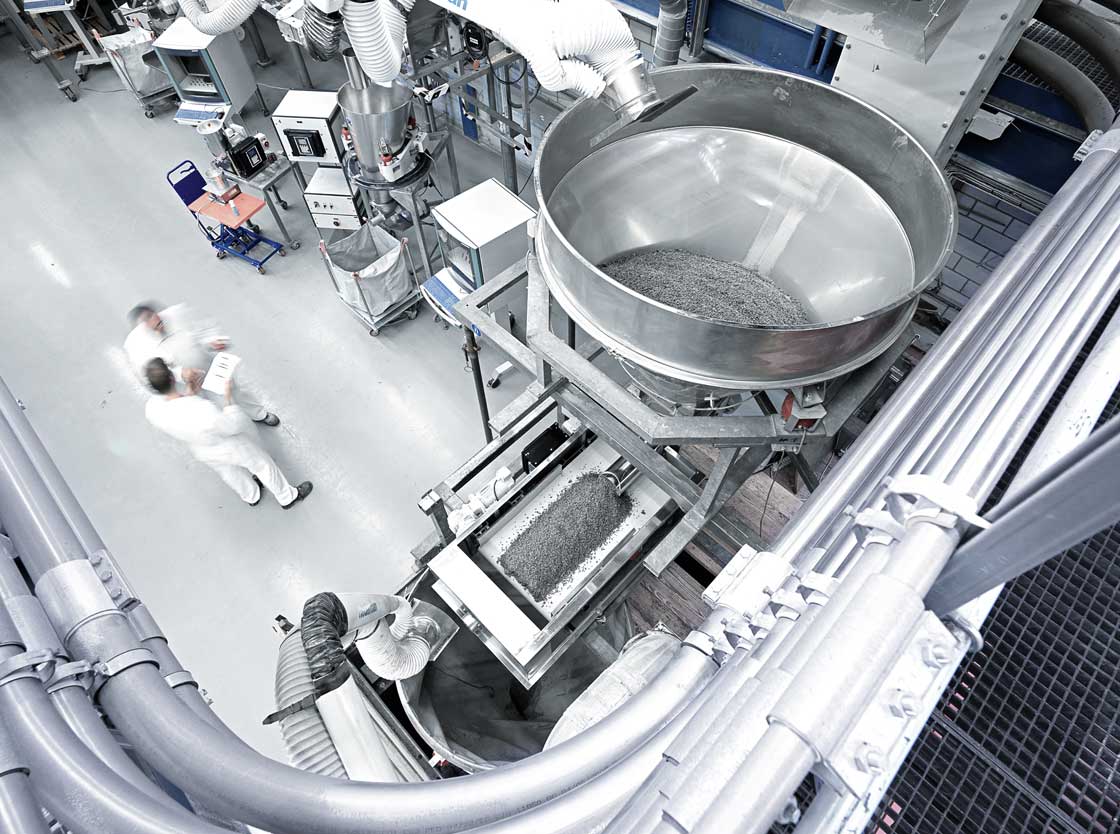

Re-melting or compounding of PCR presents its own set of challenges, primarily revolving around the poor flow characteristics and low bulk density of the bulk material. The low bulk density of PCR, especially film or sheet regrind, can significantly limit the productivity of equipment due to the inability to adequately fill the extruder’s screw channels. Coperion K-Tron’s feeding technology, whether applied to loss-in-weight screw feeders or belt feeders can feed high rates of PCR reliably. Coperion, through development work in our test labs, has developed methods to enhance the feed intake capability of the twin screw extruder. With increased feed intake, we can exploit the full performance potential of the extruder.

Extruders and feeders do not work in isolation, they rely on each other to create a quality product as efficiently as possible. The same can be said about the extrusion and feeding test centers. Together, through continuous cooperation, we are maximizing the value we provide our customers and the markets they serve.

Cameron and Lewis, thank you for the interview!