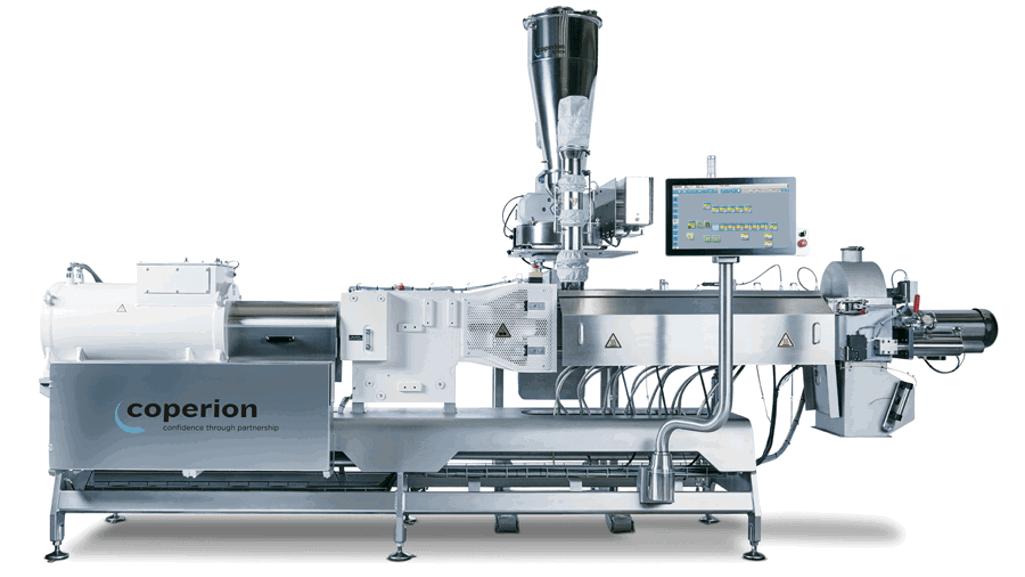

Due to the steadily growing hygienic requirements of food producers for food safety Coperion has further developed its twin screw extruder series ZSK Mv PLUS and has introduced a complete new, innovative machine design to the market.

The new ZSK Mv PLUS is equipped with an open base frame out of stainless steel. This design ensures the latest hygienic standards and provides clear advantages to operators. Cleaning efforts drop tremendously and downtime for cleaning is reduced to a minimum due to optimal accessibility of the equipment. In the same time product and production safety have been improved. Coperion uses materials of construction which guarantee the fulfillment of all EU and worldwide guidelines.