The aim of our service is to ensure the long-term performance availability of your system, minimize the risk of failure and keep the efficiency of your processes permanently high.

We offer individually tailored service packages: our service agreements. These include regular inspections, maintenance and other preventive measures. With a structured and forward-looking deployment plan, we ensure that your systems are always optimally maintained. Services are planned at an early stage, which keeps inspection and maintenance times short and significantly reduces potential damage risks. If required, we are available around the clock.

The services and costs of the service agreements are clearly predefined. This gives you full transparency and the greatest possible planning security as well as flexibility.

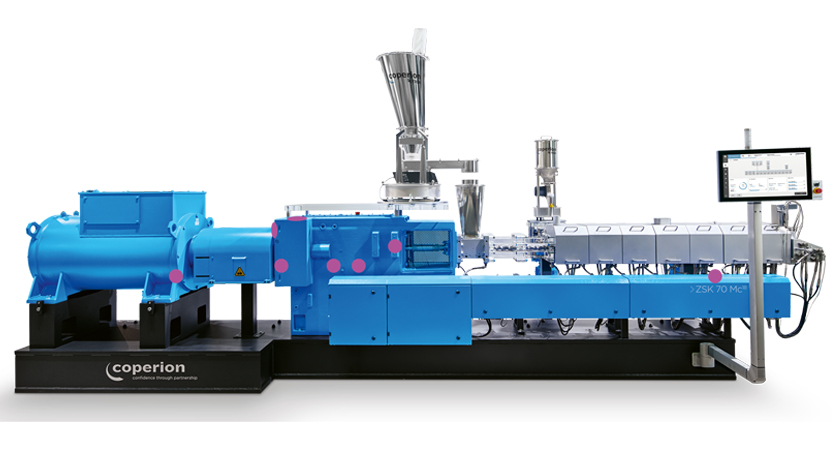

Our service agreements have a modular structure and are suitable for all Coperion systems - from laboratory extruders and compounding systems to polyolefin plants. The focus is particularly on our twin screw extruders, but components such as feeders or other system parts can also be integrated into the service packages.

Coperion

Open navigation

Coperion

Open navigation