Two-stage ZSK for separating, plasticizing and homogenization for bimodal polyolefins

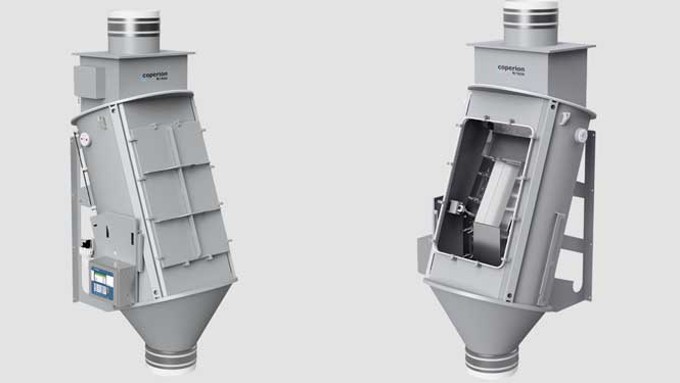

Bimodal polyethylene makes high demands on the homogenization because of the wide molecular weight distribution. The long chained molecules which are responsible for the strength in the end product must be mixed into the short chained molecule matrix. This process has a decisive influence on the later workability of the product. Coperion developed the ZSK NT which consists of two ZSK MEGAcompounders especially for this process task.

In the first ZSK MEGAcompounder the polymer is melted at a high screw speed. In the second stage the different viscosities are mixed homogeneously at low speed.

The ZSK NT technology achieves top class homogeneity and promises to supply high product qualities for future products with an even wider molecular weight distribution.

Coperion

Open navigation

Coperion

Open navigation