Compounding and pelletizing of PVC, cable and special compounds

PVC, cable and special compounds can only be processed economically with a reliable compounding and pelletizing technology. The Kombiplast from Coperion meets this demand in all respects. Coperion designed the compounding system especially for the production of temperature and shear-sensitive plastics – so that you can benefit from highest product quality, maximum economy and flexibility.

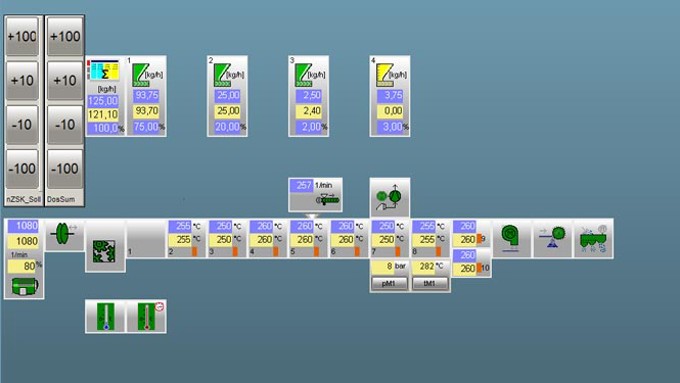

The Kombiplast KP combines a twin screw extruder ZSK with a single-screw discharge screw ES-A for gentle pressure build-up of shear-sensitive products.

Coperion specializes in the designing and building of complete turnkey plants for the compounding and pelletizing of PVC, cable and special compounds. Coperion's two-stage compounding systems Kombiplast KP are equipped with volumetric feeders, vacuum degassing and a pelletizer.

Coperion

Open navigation

Coperion

Open navigation