Deodorization in plastic recycling: from mechanical preprocesing to degassing in the extruder and removal of odor in silos. See the results at our Recycling Innovation Center.

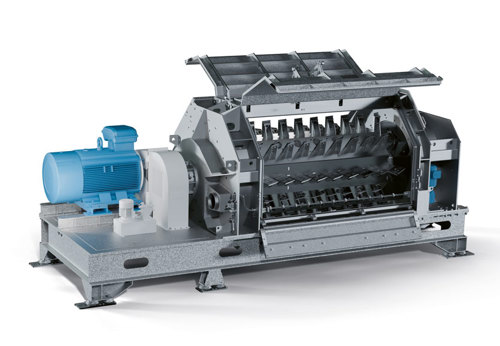

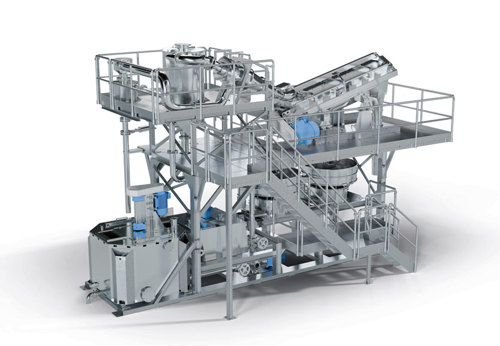

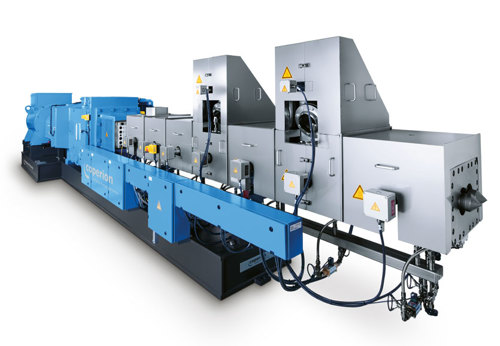

Unpleasant odors in recycled plastics caused by surface contaminants, solvent residue, additives, foreign materials, or the lingering smell of the original contents must be completely removed. It is a difficult, very multifaceted process – but we have the solution. Coperion and Herbold Meckesheim have combined their unrivaled plastics processing expertise to develop highly efficient deodorization solutions for every stage of the plastics recycling Process chain, including:

→ washing

→ bulk material handling

→ extrusion and compounding

→ finished product handling.

Suitable for post-industrial and post-consumer waste recycling, Coperion-Herbold deodorization solutions remove the source of noxious smells, including volatile organic compounds (VOCs). Our deodorization technologies are tailored to match your application requirements and desired product quality – boosting recyclate value and opening up new markets.

Coperion

Open navigation

Coperion

Open navigation