Dust avoidance. Dedusting. Dust metering

The purity of bulk materials is a critical factor in the quality of the end product. Regardless of whether the focus is on minimizing product degeneration, cleaning products perfectly or determining the residual dust to comply with standards – Coperion's solutions offer the optimal mix of many years of process competence and globally leading bulk materials expertise. Even at the design stage of the conveying plant, the Coperion specialists ensure that dust generation will be minimized. For that reason, they select suitable pipe materials and flange connections and ensure conveying velocities to be in an acceptable range.

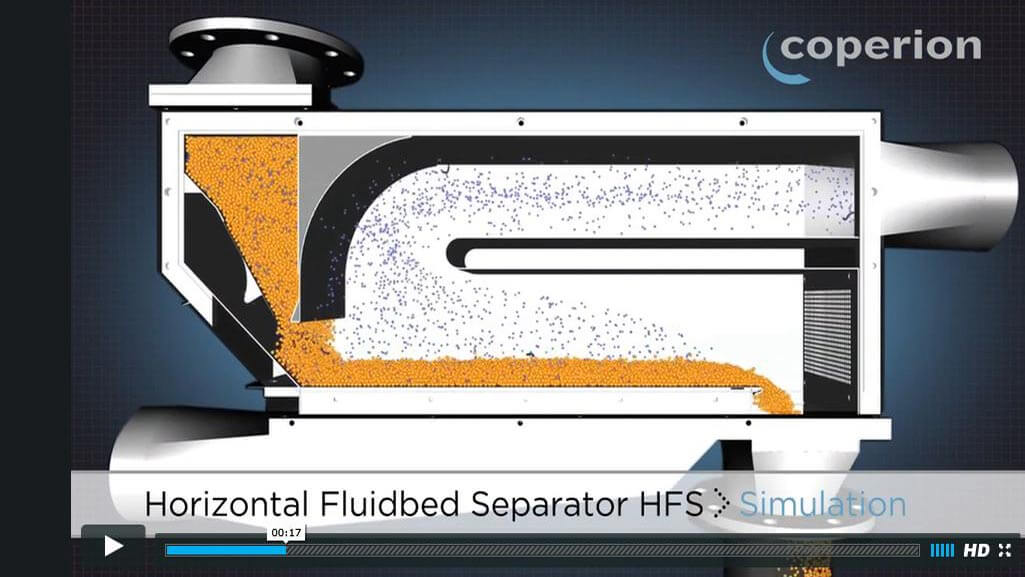

The use of hydraulic conveying systems is providing best results to meet the highest quality requirements. Our range of equipment includes sieves and separators for efficient cleaning of the product from dust and streamers.

Coperion

Open navigation

Coperion

Open navigation