What are differences in extrusion techniques between TVP (Texturized Vegetable Proteins) and HMMA (High Moisture Meat Analogues)?

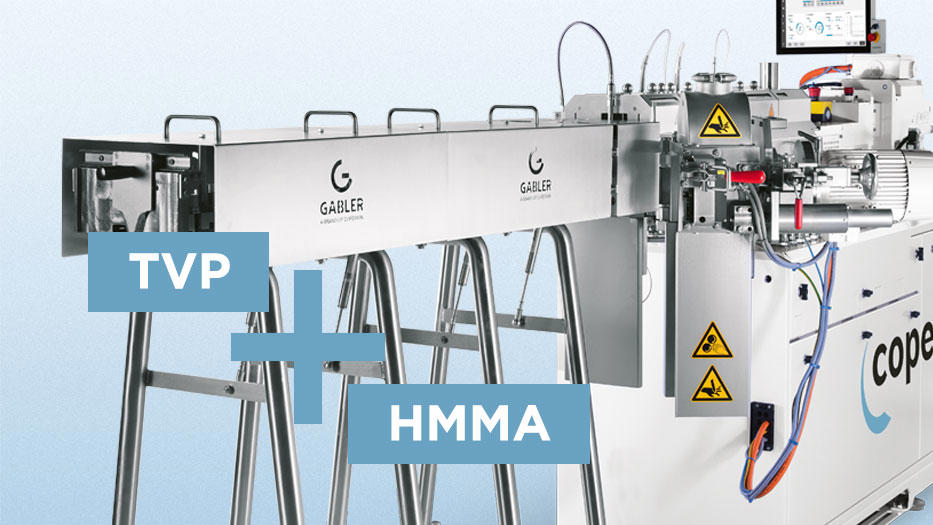

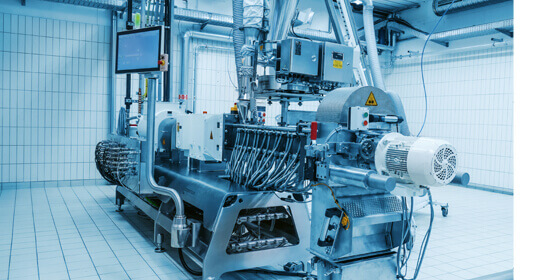

Co-rotating twin screw extruders are used for the production of both TVP and HMMA, although the set-ups for both products are totally different. The process section of Coperion’s highly efficient ZSK Food Extruder is designed as a modular system. It consists of several barrels in which the co-rotating screws operate. These screws also consist of different screw elements which can be combined individually. The advantage of this modular principle is the inherent maximum flexibility in the extrusion process.

It should be noted that Coperion’s ZSK Food Extruder has an outer to inner working screw diameter ratio (Do/Di) of 1.8, thus making it the highest free volume extruder available on the market. Its high free volume allows for a much higher capacity within a lower overall space and reduced energy profile. It is particularly beneficial when working with difficult-to-feed powders, such as proteins. The ZSK Food Extruder can be run with screw speeds up to 1,800 rpm which is also unique to the market and offers new perspectives e.g. for the extrusion of HMMA.

Extrusion of TVP

TVP is used as meat substitute or meat extender. It can be produced and used in different sizes and forms for different applications as smaller pellets or larger chunks, broken down or ground. TVP is a dry, porous (expanded) product with a long shelf life in normal ambient conditions. Before it can be used, it has to be soaked in water/ liquid.

Soy, legume and wheat protein as well as cotton seed and other proteins are used. It is important to note that protein functionality and concentration in the bulk material is important for good results. Quality parameters for TVP products include water uptake of the extrudate as well as fiber texture and length.

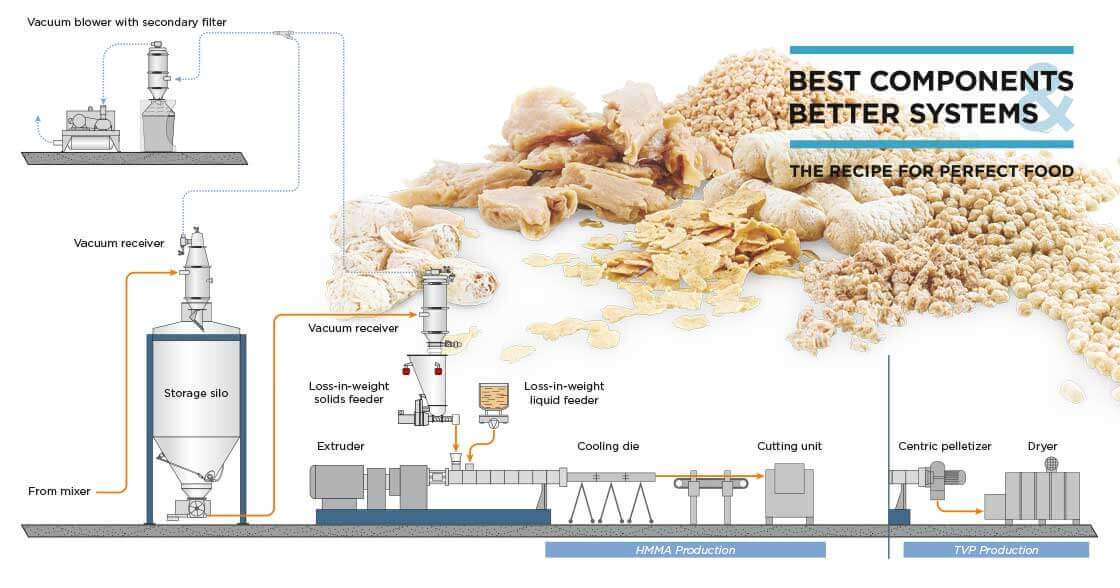

For TVP extrusion processes, the extruder is set up with a medium length process section and Coperion’s centric pelletizer ZGF. The bulk raw protein material is continuously fed into the main inlet of the extruder, and immediately after that, water is injected via Coperion K-Tron loss-in-weight liquid feeders. In some cases, direct steam injection to the process section is applied as well. Inside the extruder’s process section, the material is mixed, hydrated, then kneaded, cooked and denatured.

At the end of the extruder process section, the product exits through a special die head, inside which a certain alignment of the product is achieved to ensure a porous, foamy structure with orientated fibers. It is cut immediately by the rotating knives of the ZGF pelletizer. The TVP granules then need to be dried to be stable for long storage. TVP can be run at high production rates and large extruder sizes.

Extrusion of HMMA

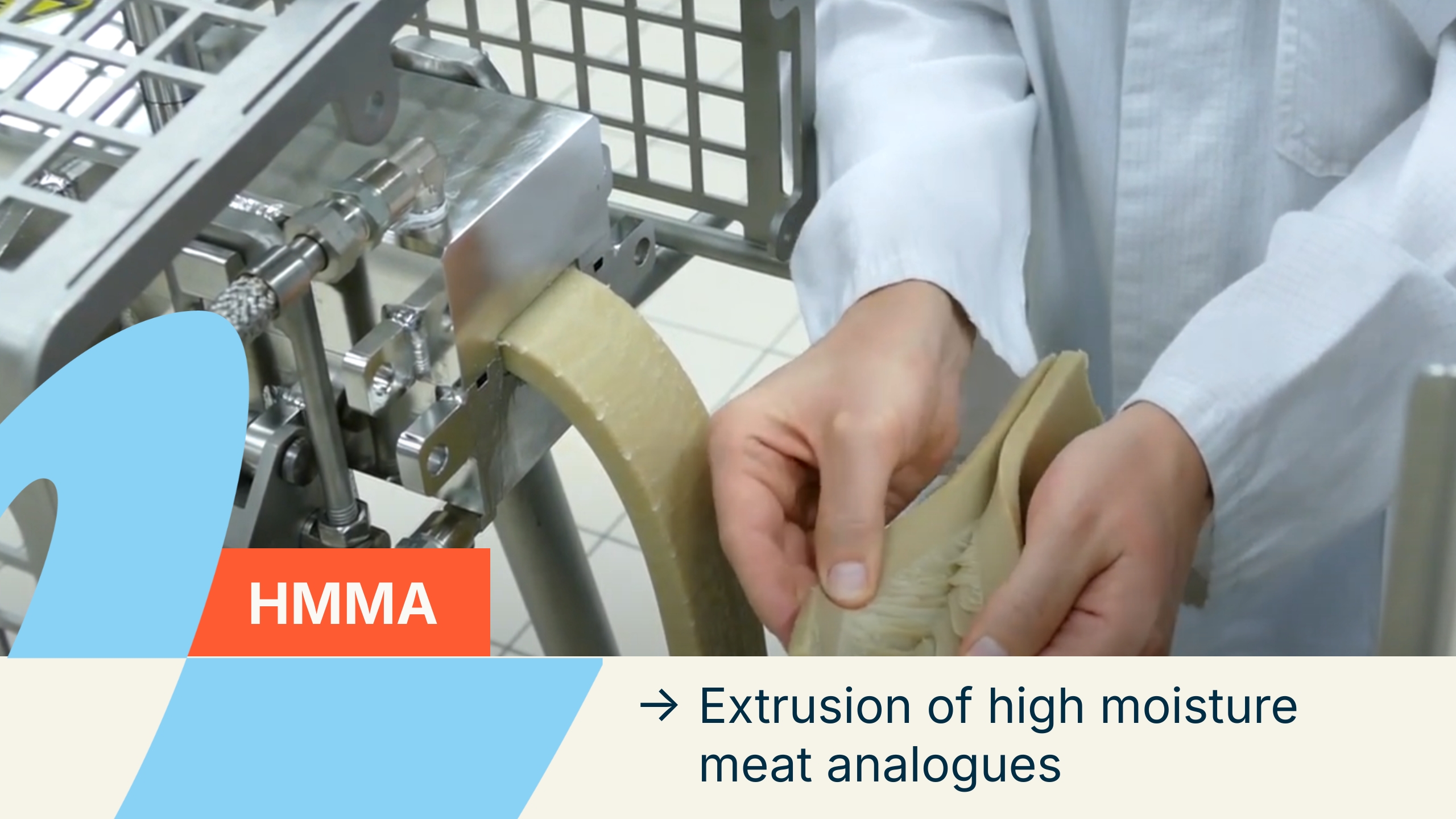

HMMA aims for high-end meat analogue products used in ready-to-eat dishes. Different structures simulating different meat types (such as pork, poultry or beef) can be achieved by adjusting recipe and process parameters. One of the most important advantages from both the consumer’s and manufacturer’s point of view are that HMMA products are amazingly similar in appearance and texture to genuine meat.

For HMMA production, the water content is similar to lean meat, about 50 to 80% extrusion moisture. Consequently, the final products need to be stored in a refrigerator or freezer and are as delicate as meat. The protein sources used for HMMA are mainly legume proteins such as soy, lupine and pea. In some cases – such as when used for actual meat extenders – reduced amounts of genuine meat, fish, milk or wheat proteins are added to the recipe.

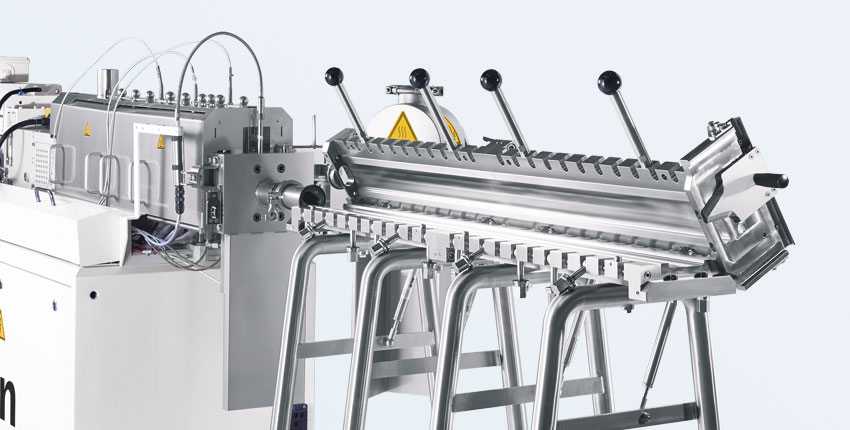

In the HMMA process, the process section of the ZSK Food Extruder must be quite long and a special cooling is attached directly to the extruder. Raw protein materials are fed into the inlet of the extruder and water is injected directly after that. Inside the process section of the twin screw extruder, the mass is mixed thoroughly, then the proteins are hydrated, kneaded, plasticized, and denatured under high mechanical energy input. The mass is pushed by the extruder into the cooling die where it is cooled down and forced into laminar flow. Here the transformation to solid phase takes place, building fibers by “freezing” the laminar flow profile into meat-like structures. The meat analogues usually exit the die as a rubbery strand or ribbon. This ribbon-like material is then conveyed to further processing steps.

Coperion

Open navigation

Coperion

Open navigation