A versatile concept for the accurate feeding of liquids and pastes

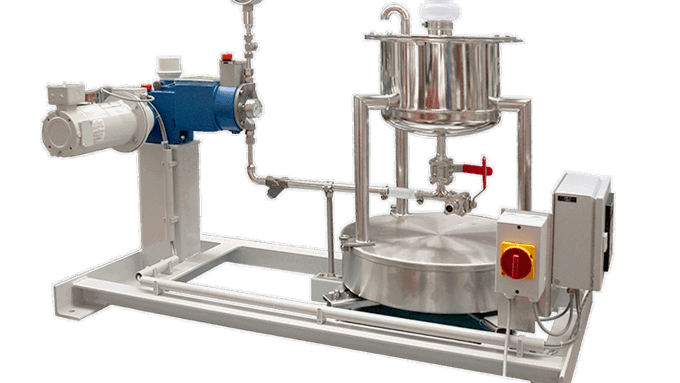

Coperion K-Tron’s liquid loss-in-weight feeders provide accurate continuous volumetric or gravimetric flow control of liquids. The highly accurate gravimetric units combine the pump and tank with a suspension scale or platform scale; the feed pump for metering the material is located outside the scale area.

When feeding liquids, the special requirements of each application vary. A wide range of pumps and tanks can be combined to constitute a Liquid Feeder and satisfy the specific demands. The feed pump is selected according to the material and the required feeding capacity.

Coperion

Open navigation

Coperion

Open navigation