Twin Screw Extruders, Feeders and Valves that Raise Your Throughput and Efficiency in Compounding Engineering Plastics

The properties of engineering plastics make them indispensable nowadays in the construction of vehicles and machinery, power and electrical engineering, domestic installation and for sport and leisure articles. The processing ranges from coloring and alloying of base polymers right through to incorporating organic and inorganic fillers and reinforcing materials.

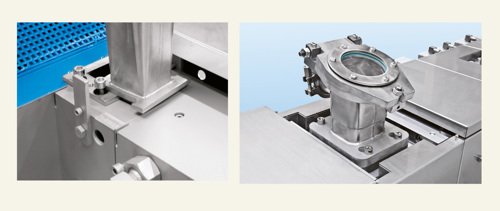

From single components like feeders or valves to high-performance compounding systems and extruders or total solutions, Coperion has the right solution for your process. Our expertise includes material handling, raw material feeding, compounding and the entire downstream process, allowing us to design systems that exactly meet our customers’ specifications. We deliver solutions to engineering plastics processors that ensure maximum throughput rates with greatest possible efficiency and highest product quality.

Coperion

Open navigation

Coperion

Open navigation