Superior Solutions for Material Handling, Feeding, Extrusion, and Pelletizing

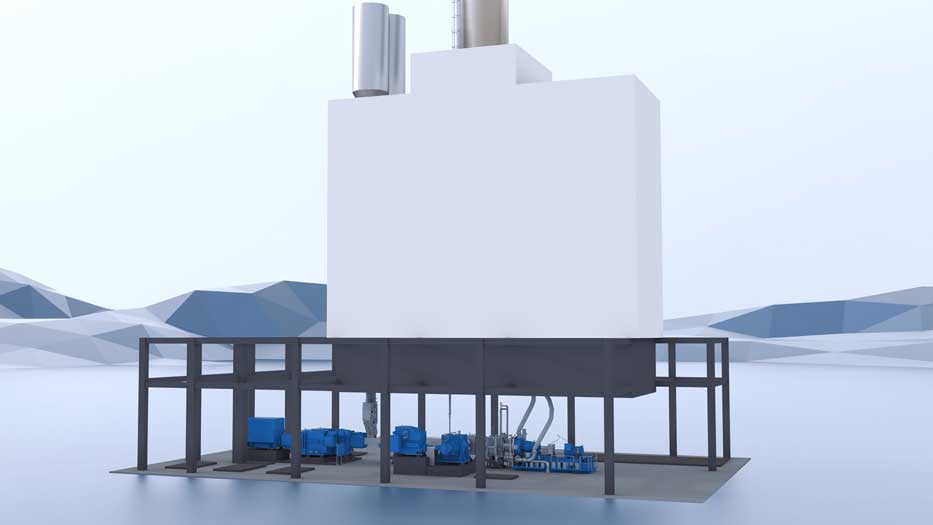

Coperion has a long history as a proven partner for the design and realization of complete polyolefin production plants.

As market and technology leader, we have a unique wealth of now-how for all process stages along the polyolefin production chain – from material handling, powder and pellet mixing to feeding, extrusion and devolatilization through pelletizing and storage.

Coperion

Open navigation

Coperion

Open navigation