Gentle high rate gravimetric feeding or metering of free flowing or friable products

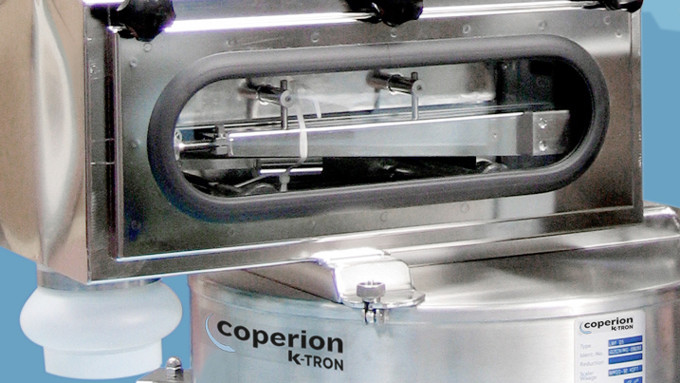

Weigh Belt Feeders are relatively simple, extremely reliable gravimetric feeders providing high feeding precision and efficient process monitoring. They can be used as a feeder, batcher, or meter. The SWB is the perfect solution for wild flow metering, where headroom is limited, or when feeding friable material that may be damaged by other feeding methods. This compact gravimetric feeder can handle large volumes of bulk material with different flow characteristics.

Optionally, the SWB-300 and SWB-600 offer continuous online taring by using two weigh modules. This reduces costly maintenance, line shutdowns and laborious manual calibration while at the same time substantially improving long term accuracy and stability.