Why Efficient Material Handling Matters in Battery Production

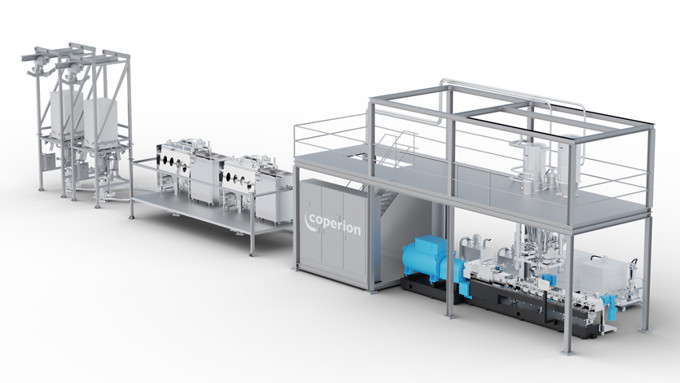

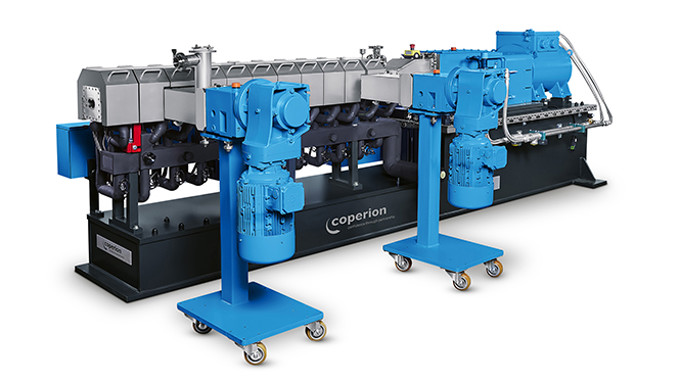

Efficient, reliable, and contamination-free material transfer is essential for modern battery manufacturing, where precision, product integrity, and safety standards define overall production success. With decades of expertise in bulk material handling and pneumatic conveying, Coperion delivers advanced end-to-end solutions engineered specifically for handling abrasive, fine, and highly sensitive battery raw materials. From wear-resistant rotary valves to customized open and closed loop pneumatic conveying systems, our technology ensures continuous, dust-controlled, and maintenance-optimized operation throughout every phase of battery production. Backed by extensive experience, we help battery producers streamline plant layout, reduce lifecycle costs, and achieve long-term system performance with maximum uptime and process stability.

Coperion

Open navigation

Coperion

Open navigation