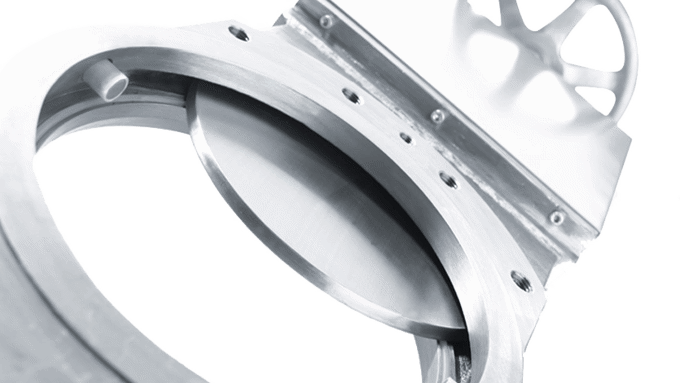

Ideal for applications that require a sanitary design

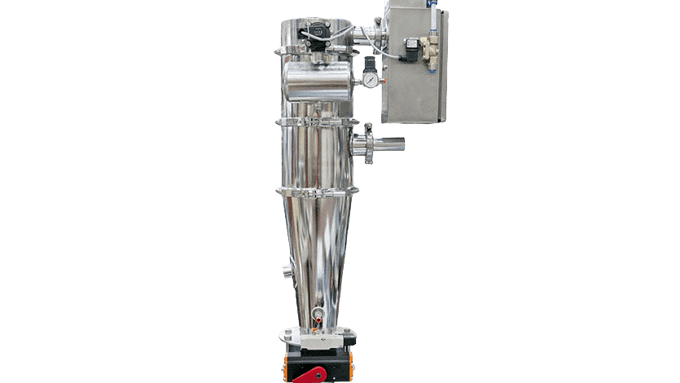

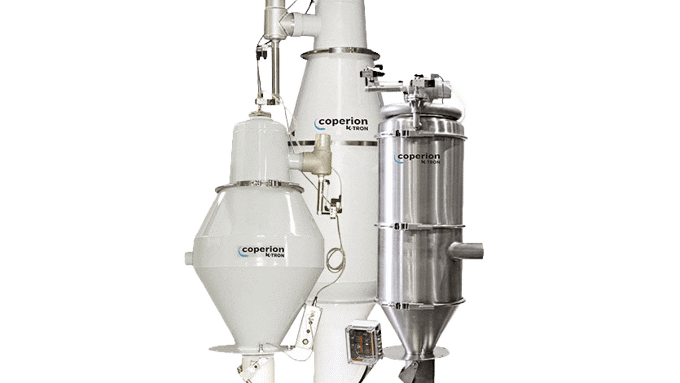

P-Series receivers are designed to convey bulk solids and meets the rigid sanitary requirements of the food and pharmaceutical industries.

The Coperion K-Tron P-Series sanitary receivers can be used for gain-in-weight or loss-in-weight feeder refill applications, simple up and in systems or engineered for larger, central vacuum conveying systems.

Coperion

Open navigation

Coperion

Open navigation