High-capacity sifting, ultra fine grinding and controlled particle size distribution

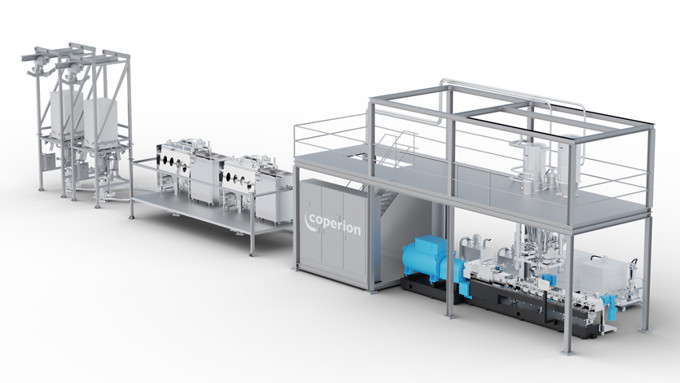

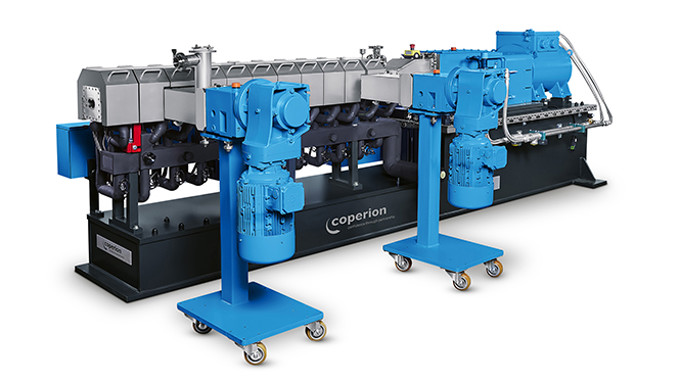

Coperion offers a variety of sifting, milling and grinding solutions.

Our centrifugal sifters are used to screen, separate and remove material of different sizes, at high rates and very efficiently.

With the Kemutec range of mills the process of particle size reduction will be quick, flexible, clean and easy for the operator. While our range for size reduction solutions is extensive, all our equipment will be customized to suit our client’s need, their material, as too, the process. Our global experts will help solve your size-reduction challenges and ensure you receive the highest level of support.