Production of heavy layer by the split-feed method

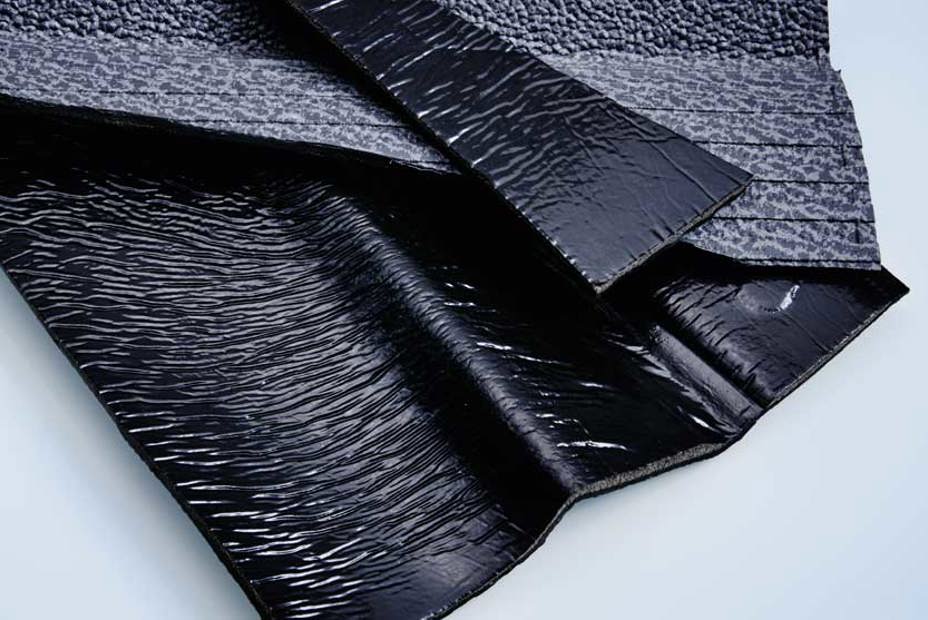

Coperion processing lines have proven themselves for the production of highly filled heavy layer compounds over many decades. Heavy layer compounds are used in the automobile industry for damping engine and driving noise. The extruded films are often backed with felt, foam or carpet. They are then formed into the desired shape on presses or by deep drawing and cut.

Due to the gentle raw material handling and the resulting high product quality, the split-speed process with the twin screw extruder ZSK is the most common production method for heavy layer compounds. In this process the backbone polymers/elastomers, small additives and some of the liquids are fed into the first barrel of the Coperion extruder in separate streams and weighed gravimetrically by Coperion K-Tron feeders. Abrasive fillers are added to the plastic compound downstream by a twin screw side feeder.

In addition to the split-feed production method, heavy layer can also be produced by direct extrusion / inline compounding.