Production of highly filled flame retardant cable materials

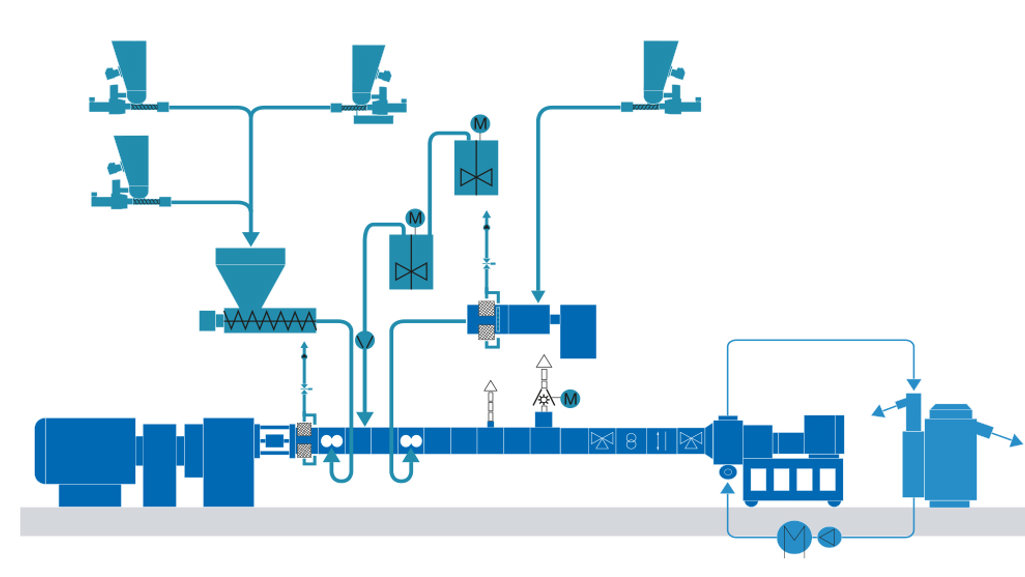

Consistency, reproducibility and product purity are major requirements for the production of highly filled flame retardant cable materials (HFFR). Coperion's HFFR processing lines completely satisfy these requirements. Coperion is a specialist for such complete processing lines for HFFR – from raw material handling and feeding to compounding, pelletizing, cooling and packaging the pellets.