The K3 Vibratory Feeder is built around a new shock absorber design, the heart of the system. Instead of rubber or spring shock absorbers, which are typically used in conventional vibratory feeder designs, Coperion K-Tron has developed the new vibratory feeder with a flexible pendulum technology. As a result, shock absorption only takes places parallel to the desired direction of motion. Unintended rotational movements as well as excessive pulsation can thus be reliably eliminated. This new approach has a number of key benefits.

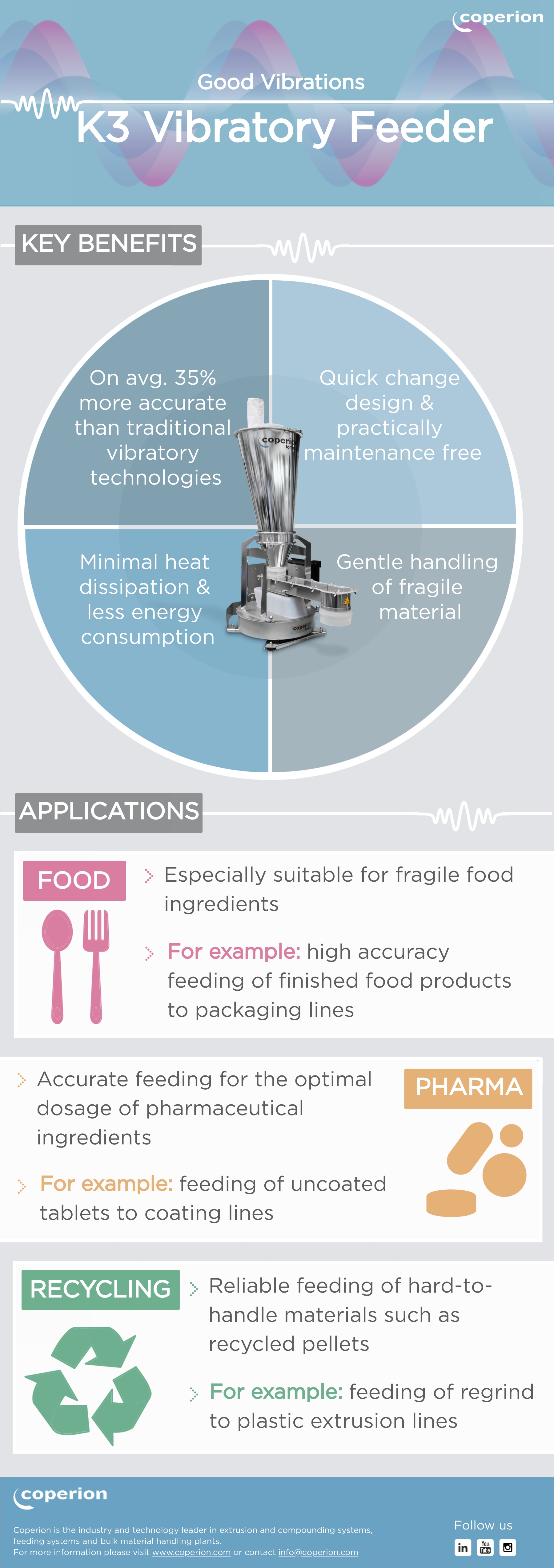

To begin with, the new design proved to be on average 35% more accurate than former vibratory technologies making the K3 a game changer in many industrial sectors. The quick change design is helpful for manufacturers with frequent product changes and cleaning cycles, for example in the food industry. Additionally, the feeder does not come with any mechanical wear parts, making the system practically maintenance free. Furthermore, the K3 Vibratory Feeder consumes less energy and does not dissipate an excessive amount of heat to the environment. At the same time, fragile materials are handled even more gently than before making the feeder ideal for many applications in the food, pharmaceutical and plastics industry.

The K3 Vibratory Feeder is suitable for various applications – especially when non-homogeneous and hard-to-handle materials are involved or if high feeding accuracy is necessary. The following scenarios illustrate three possible applications:

Food: In the food industry, manufacturers are often confronted with fragile food products that need to be accurately handled and fed. The K3 Vibratory Feeder in hygienic design can be optimally used to feed the finished product to the packaging lines.

Pharma: In the production of pharmaceuticals, accurate dosing is required in order to achieve the right composition of ingredients. One example where the K3 can yield an advantage is the feeding of uncoated tablets to a coating line.

Recycling: This new technology also represents a benefit for the plastics industry. Recycled materials are known for their non-homogeneous properties. The new K3 Vibratory Feeder can be used to feed regrind to plastic extrusion lines, for instance.

Coperion

Open navigation

Coperion

Open navigation