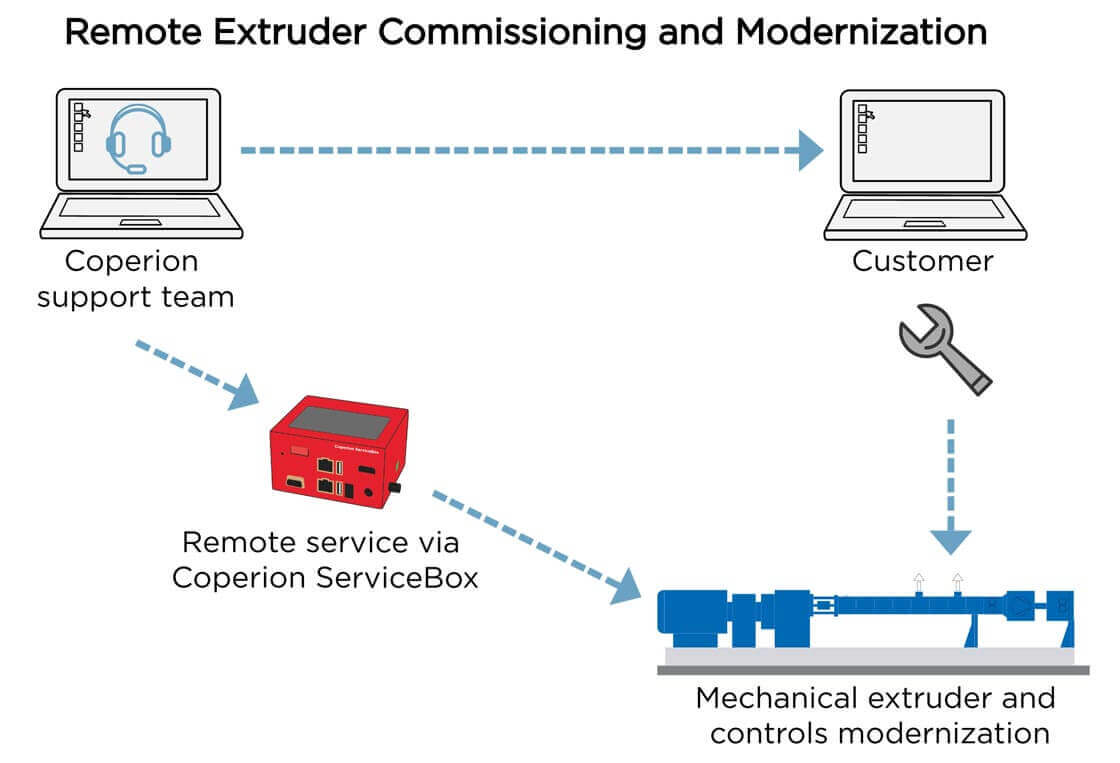

Coperion successfully achieved the complex modernization of a ZSK 250 high-capacity extruder completely utilizing remote processes and support. As this recent example shows, Coperion has successfully evolved its modernization efforts to utilize the Coperion ServiceBox, an integrated system for online monitoring and failure recording in extruders and compounders, as well as communication methods like video and telecommunication to complete customer requests. This ZSK 250 extruder modernization package encompassed both a control software update and mechanical overhauls on the system. A significant throughput increase was achieved on the extruder by modernizing the gearbox, mounting a new coupling, installing a ZS-EG side devolatilization and updating the EpcNT control, including a rebuild of the control cabinet and monitor. Coperion’s three member team, based in Stuttgart, Germany, worked directly with the customer to ensure proper software and mechanical updates. During this time when travel is limited by the pandemic, this achievement serves to show that Coperion is committed to the continued reliable rollout of its customer projects and hence their success.

Blueprint For Further Projects

Although Coperion has been utilizing the Coperion ServiceBox for many years to perform remote software updates on its extrusion systems, more complex mechanical remote tasks have been limited so far. With the successful modernization of this ZSK 250 high-capacity extruder, the proof of concept has been realized and a milestone has been set for complex maintenance and modernization projects utilizing remote service. Whether under the current pandemic condition or as customers fundamentally shift work expectations, Coperion offers a lean, flexible solution for machine commissioning and modernization of its extruders.

Stefan Lachenmayer, Head of Coperion’s Extruder Modernization team, is very confident in the future potential. “Through partnership and planning with our customers we can successfully execute complex remote projects. This recent success proves as another milestone in Coperion’s ability to evolve to meet current market requirements and successfully coordinate both mechanical and software modernization tasks utilizing the latest communication technology. We, as Coperion, are committed to supporting our customers via remote commissioning and modernization for both for large-scale extruders as well as refurbishing projects of any size.”

Coperion

Open navigation

Coperion

Open navigation