The new C-Rock wear material is characterized by its highly wear and corrosion resistant matrix with specially selected hard material components. It is applied to product-contact parts of the ZSK extruder barrels using a technologically advanced manufacturing process. The result is a completely homogeneous, closed surface screw channel and first-class adhesion of C-Rock to the base material.

C-Rock gives the highest protection against abrasion and corrosion to the barrels of Coperion ZSK extruders. It allows for highest productivity even in difficult applications with aggressive products and extends the life of the barrels.

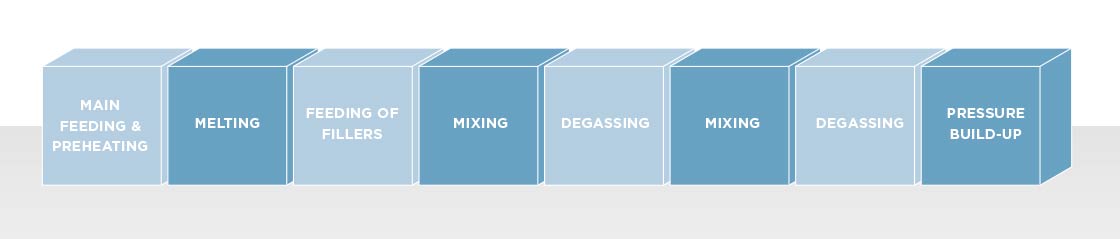

C-Rock is particularly effective in heavily stressed areas of the process section such as in the melting zone, when mixing in abrasive particles, fibers or powders, and in the pressure build-up zone. These zones are when C-Rock is most worthwhile to apply, keeping barrel wear to a minimum and ultimately increasing the efficiency of the entire extrusion line significantly.

- Coating thickness of 1.5 mm

- First-class adhesion of the coating to the base material

- For closed standard barrels

- For extruder sizes ZSK 70 and ZSK 92

- Available as directly coated barrels and liners

- Retrofitting of liner barrels with C-Rock possible

The wear material C-Rock is particularly suitable for compounding PA, PBT, PP, HT plastics with glass and carbon fibers, ceramic masses, metal masses and powders. We recommend C-Rock for extruder barrels in the melting, mixing and pressure build-up zones of the process section.

Coperion

Open navigation

Coperion

Open navigation