After over five decades and six generations of innovation and development, Coperion K-Tron’s Smart Force Transducer (SFT) technology continues to set the standard for the industry. Advanced single-wire design, high resolution, internal force reduction, and 90% fewer parts combine to provide the highest possible levels of performance and reliability.

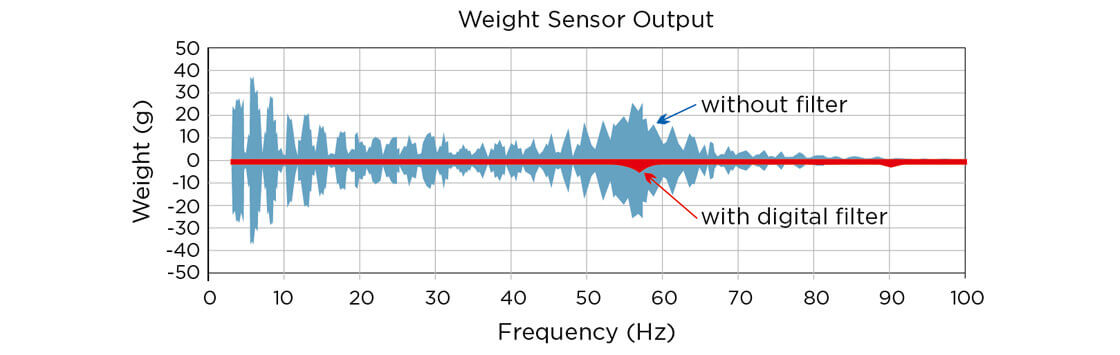

Consider a loss-in-weight feeder operating in a typical plant environment. Feed rate control is achieved by continuously weighing the entire feeding system, then controlling the rate at which the system loses weight by adjusting motor speed or vibrator amplitude to achieve the desired setpoint. The total load applied to the weighing system is the sum of the actual weight of the feeder and bulk material plus the variable force contributed by in-plant vibrations. No matter how accurate its scale system is, a loss-in-weight feeder is worthless if the weight readings are tainted by vibrations. Many feeders stand in the midst of harsh industrial activity, making its ability to accurately measure the actual loss in system weight crucial to its performance. Possible agents of measurement contamination include shock, vibration and other perturbations such as drafts, and even convective air currents.

Coperion

Open navigation

Coperion

Open navigation