The market for plant-based meat substitutes is growing exponentially, with economists predicting the demand for alternative proteins to reach between $77 billion and $153 billion by 2030. This is a 15 times increase from demand in 2021 and is driven primarily by personal health, animal welfare concerns and a desire to limit the effects of climate change.

Plant-based meat substitutes are used to create a wide variety of consumer products like vegan mince, vegan nuggets, and products made to resemble their meat equivalents like pulled pork. There are only two primary plant-based intermediate products used to make most consumer products – Texturized Vegetable Proteins (TVP) and High Moisture Meat Analogues (HMMA).

Sign up for the Coperion newsletter to receive the latest updates

How to expand production to include both TVP and HMMA

Learn more about the production of Textured Vegetable Proteins (TVP) and High Moisture Meat Analogues (HMMA) with the ZSK Food Extruder in Hybrid Version.

TVP and how it is made

TVP has an expanded fibrous structure with large gaps left when water evaporates at high temperatures. It is processed at a moisture content of 10 to 30 percent, which is lower than HMMA. TVP is the equivalent of a dehydrated meat product and must be soaked in water to produce consumer products like burgers, chicken strips or mince.

The heart of the manufacturing process for plant-based meat substitutes is Coperion’s ZSK Food Extruder. Co-rotating twin screws in enclosed barrels provide the conditions and sequence of operations to create TVP out of protein powders, water and other ingredients. A typical manufacturing process includes these steps:

- Firstly, the ingredients are homogeneously mixed.

- Secondly, the materials are kneaded, plasticized and a melt is formed.

- Thirdly, the proteins in the melt are denatured, and the protein molecules break down and reform in the required structure.

TVP quality is measured by its fiber texture, length, and strength. The ideal protein content should be between 50 and 80 percent because higher percentages can cause a gummy product of low quality. Fat content of more than 5 percent can also prevent fiber formation, and too much water gives a mushy texture with fewer visible fibers.

Conditions in the ZSK Food Extruder also contribute to product quality. Too much energy from screw speed and configuration turns the product brown. On the other hand, too little energy limits the amount of expansion in the product giving a poor texture to the TVP.

At the end of the extrusion process, TVP passes through a die plate which aligns the product fibers. After this, Coperion’s centric pelletizer ZGF cuts the melt strands into granules for drying and storage. A well-designed recipe and manufacturing process will result in high quality TVP exiting the extruder with firm texture and visible fibers.

HMMA and how it is made

HMMA has a dense, fibrous structure similar to muscle meats. It contains 50 to 70 percent moisture and must be stored chilled or frozen. HMMA can be used to create ready-to-eat dishes like chicken chunks or minced meat.

HMMA is also formed in the ZSK Food Extruder, but the materials are processed at a higher water content. Fiber length and strength are features of HMMA quality, as well as product texture and firmness. HMMA contains 50 to 70 percent water and 30 to 50 percent protein with less than 10 percent fat content. Process moisture is a critical parameter for HMMA quality with too much water giving the product a brittle texture and light color.

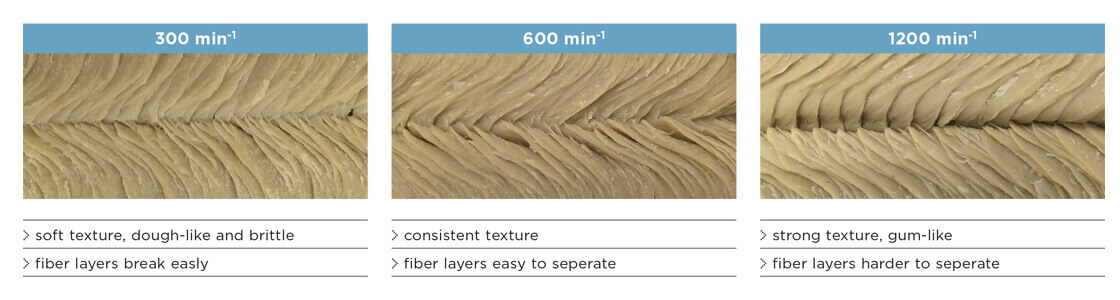

Mechanical energy from the extruder screws is an essential parameter for HMMA. While too high screw speeds can lead to products with gum like fiber layers that are hard to separate, too low speeds can result in a soft texture that is dough-like and brittle. With an optimum screw speed HMMA has a consistent texture and easy to separate layers.

When HMMA leaves the ZSK Food Extruder, it passes through a cooling die, which forces the product into a laminar flow. The resulting rubbery strand or ribbon is cut into segments for further processing or storage in a freezer.

Using Coperion’s ZSK Food Extruder in Hybrid Version to make TVP and HMMA

Even though TVP and HMMA both use an extrusion system, the process conditions vary significantly. Depending on the recipes for each product, the process zones in the extruder and the energy inputs differ to meet the process conditions required for each. The extruder discharge must be changed when switching between TVP and HMMA.

Coperion’s ZSK Food Extruders in Hybrid Version take all these differences into account and enable the production of TVP and HMMA on one and the same line. They use an adapter at the end of the process to make switching between pelletizer and cooling die easier. Machine operators can perform the changeover in less than two hours without external support. These ZSK Food Extruders in Hybrid Version are especially useful for smaller production facilities, pilot plants or research labs. Once a recipe has been perfected, it can be scaled into a larger production facility.

Cleaning is a vital element of switching between TVP and HMMA production. Cross contamination of products will have a severe impact on product quality. The ZSK Food Extruder has twin screws with a self-cleaning profile so that there are no stagnant zones over the entire process section. This makes it easy to convert from one product to the other.

TVP production requires pelletizers and driers, while HMMA production needs chillers and freezers. The higher the production rates, the larger these pieces of equipment must be, making it less practical to use the same production line for both products.

An expert in extrusion, feeding and weighing

Coperion provides complete systems to manufacture both TVP and HMMA. We have Food Test Centers available, support in developing new recipes and testing the performance of new raw materials and provide comprehensive trainings. The ZSK Food Extruder offers the highest throughput capacity on the market. It has a modular design that allows for maximum flexibility in process set-up. There is a constant outer to inner working screw diameter ratio regardless of extruder size, which makes it easy to scale a recipe for increasing production rates.

Contact Coperion to learn more about how you can expand your production to include both, TVP and HMMA.

Your Contact

-

John Sheehy

- email: jsheehy@coperionktron.com

- telephone: +1 785 825 1611

Coperion

Open navigation

Coperion

Open navigation