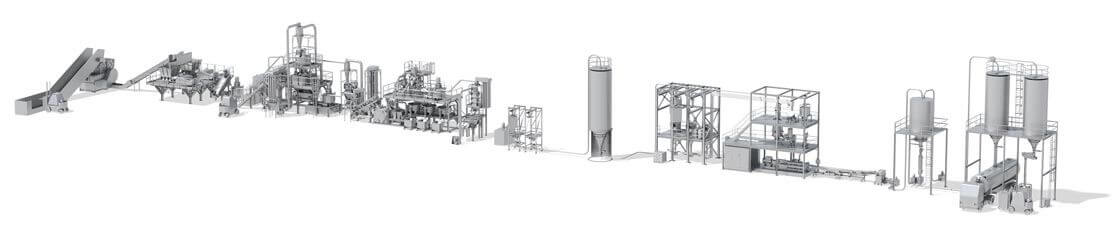

Complete systems for industrial-scale plastics recycling from a single source – the recently completed merger between Coperion and machine manufacturer Herbold Meckesheim makes it possible. We are now able to offer modular system and plant solutions that combine our complementary technologies to benefit customers. From mechanical processing – shredding, washing, separating, drying and agglomerating of plastics – to bulk material handling as well as feeding and extrusion all the way to compounding and pelletizing, the systems that we develop cover the entire process chain for reclaiming plastics. Moreover, we provide a combined global sales and service network.

Sign up for the Coperion newsletter to receive the latest updates

Making the Plastics Economy Even More Circular

Complete plastics recycling solutions

PET recycling

PET recycling is one example that illustrates how we will be able to implement a complete system for plastics recycling in the future. As the plastics industry makes advances towards a circular economy, PET plays an ever more important role due to its increasing use in disposable and reusable bottles and its recovery through deposit systems, along with other factors. This material possesses outstanding recycling properties, regardless of whether it is to be recycled in bottle-to-bottle, bottle-to-film/sheet, or bottle-to-fiber processes, or whether it comes from other product streams.

Complete PET recycling solutions from Coperion and Herbold Meckesheim offer throughput performance of up to ten tons per hour. The quality of PET recyclate manufactured using our recycling technology and decontaminated in an SSP (Solid State Polycondensation) reactor is so high that it is approved by the U.S. Food and Drug Administration (FDA) for direct contact with food.

One unique feature is that virgin material and various recyclates – such as regrind, agglomerates, or flakes – can be processed together, even if they exhibit different IV (Intrinsic Viscosity) values. Compared to conventional PET recycling procedures, our solutions save on operation and energy costs and create less logistic efforts. With comprehensive process know-how, we tailor each system individually to the respective recycling process. A wide variety of our key technologies are used:

- SML 60/100 SB 2 Granulator

This is a granulator used for crushing PET bottles and is suitable for wet operation. One unique feature that it offers is horizontal force feeding using screw feeders. The granulator allows for space-saving installation and easy material feeding. Up to two tons of polyolefins or more than one ton of film per hour is processed.

- T 2016 PA Mechanical Dryer

This mechanical dryer is suitable for various materials such as film, regrind, and mixed and rigid plastics. Thanks to its optimized design and the position of the exchangeable, wear-resistant paddles, it achieves up to 50% higher drying performance than its predecessor.

- HV 70 Plastcompactor

The high-performance HV 70 Plastcompactor from Herbold Meckesheim processes material in continuous operation between one rotating and one fixed compactor disk, each equipped with screwed-on and easily replaceable kneading bars. Since the material leaves the compactor zone within a fraction of a second, the thermal impact upon the plastic is very low. The process is regulated using two parameters – the screw speed and the distance between the disks.

- FLUIDLIFT ecodry®

The FLUIDLIFT ecodry® process dries the regrind while it is being conveyed to the extruder. A flash dryer specially modified for recycling regrind removes the moisture remaining after the washing process. Moisture content is significantly reduced which optimizes the energy consumption of the downstream process and leads to improved end product quality.

- Smart Weigh Belt (SWB) Feeder

For feeding flakes and fiber, a Smart Weigh Belt (SWB) feeder can be used. This low-headroom gravimetric feeder can feed large quantities of bulk material into the extrusion process at high accuracy, even at low and variable bulk densities.

- ZSK Twin Screw Extruder

Coperion ZSK twin screw extruders are the heart of the plastics recycling process. With their high-performance processing properties and high devolatilization performance, ZSK twin screw extruders are suited to energy-efficient recovery of plastics of all sorts. The ZSK extruder features high end product quality with gentle product handling, short residence time, intensive devolatilization, and outstanding dispersion with concurrently high throughput performance.

- Product Discharge

Diverters, melt pumps, and screen pack changers follow the extrusion step. Depending upon whether pellets, fiber or film are to be manufactured from the PET, we provide water baths and underwater pelletizers, fiber spinning pumps or film stretching lines as part of our complete solutions.

New Recycling Innovation Center

In June 2022 we started the construction of a state-of-the-art Recycling Innovation Center. This new test center for recycling applications is located in immediate proximity to our existing test center for bulk material handling at the Niederbiegen/Weingarten production facility in Germany. In the future, every major step of the plastics recycling process can be tested under production conditions and results can be examined by customers down to the smallest detail prior to making an investment.

Your Contact

-

Jochen Schofer

Head of Sales I Business Unit Recycling

- email: jochen.schofer@coperion.com

- telephone: +49 711 897 3176

Coperion

Open navigation

Coperion

Open navigation