Mobile phone cases are typically considered single-use products; they're made of virgin plastic and when the consumer changes phones, often the case no longer fits the new phone so they become redundant and end up in landfills. But...could there be another way?

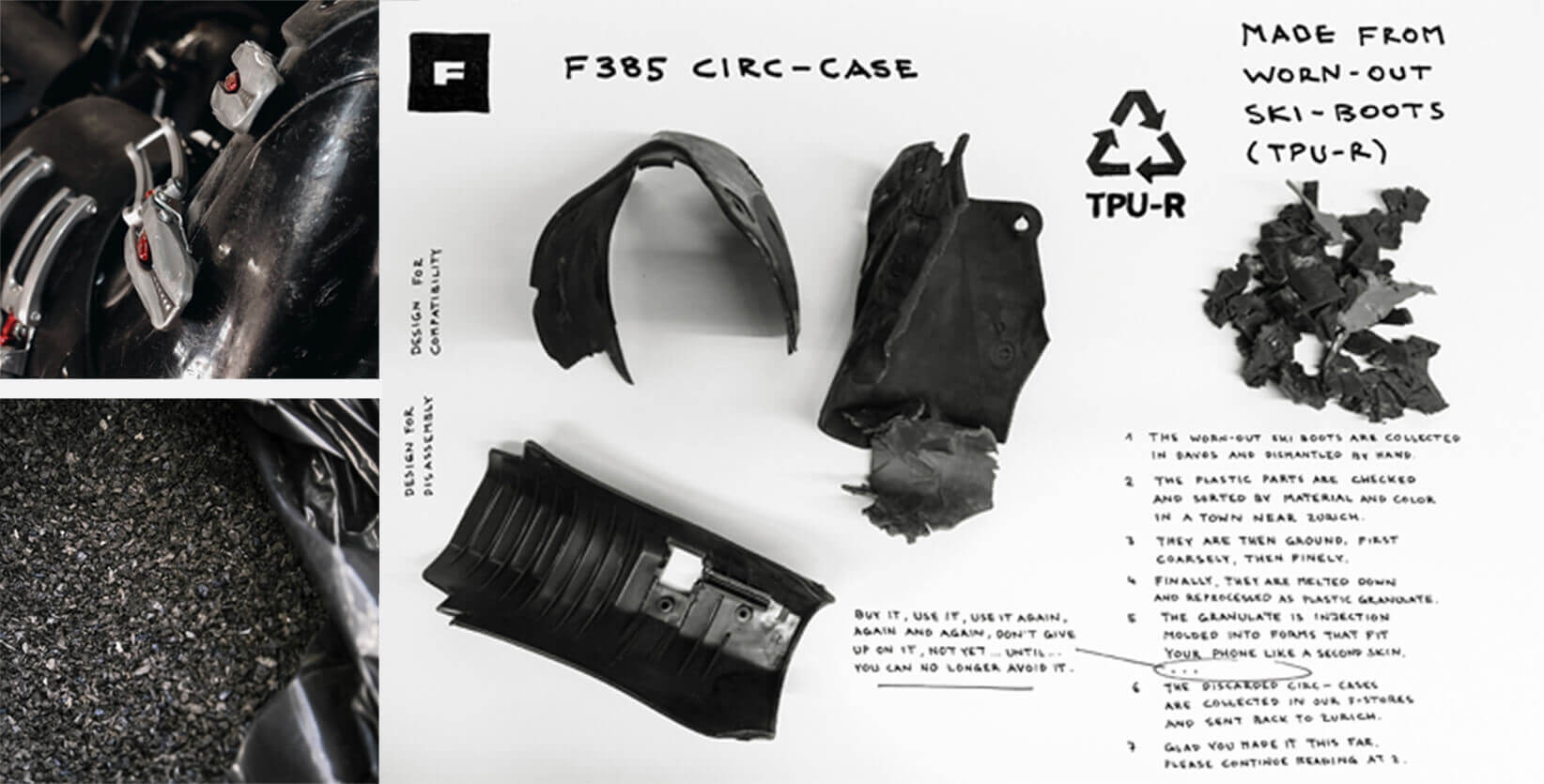

FREITAG, a company that has already made a name for itself with numerous innovative upcycling projects, took up this very question, and the answer is yes! The F385 CIRC-CASE is a mobile phone case made entirely from recycled ski boot shells.

Together with the Argo Employment Opportunity Workshop in Davos, the IWK Institute for Materials Technology and Plastics Processing in Rapperswil, Switzerland, and other partners, FREITAG turns worn-out ski boots into recyclable protective iPhone® cases that not only look good, but can also protect future iPhone® models as well.

In this article, you’ll learn more about the F385 CIRC CASE protective case’s circular process, and which roles Coperion’s feeding and ZSK extrusion technologies fulfill within that process.

STEP 1: GRIND THE SKI BOOTS

Ski boot shells consist primarily of thermoplastic polyurethane (TPU-R). FREITAG's process exploits this valuable raw material to full advantage. At Argo’s employment opportunity workshop in Davos, worn-out ski boots are collected, taken apart and separated from their clasps and other plastic parts.

Coperion

Open navigation

Coperion

Open navigation