Highly sophisticated solutions for the control of extrusion lines

Coperion provides control solutions for twin screw extruder systems individually tailored to customers’ requirements ranging from standardized control systems to customized open control systems for complete compounding plants.

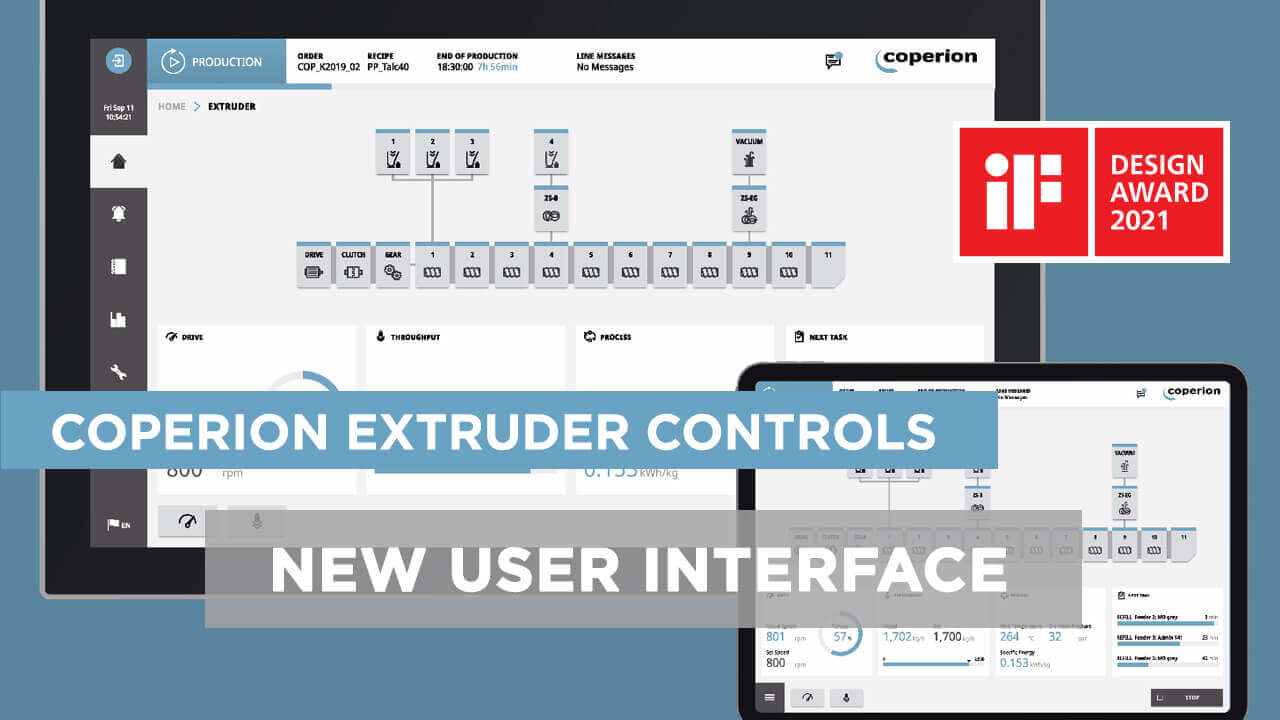

The control systems can be easily integrated into customers’ Industry 4.0 environments and offer a large number of functions such as the full recording of production data, reporting, recipe management and much more. The clearly designed, userfriendly interface of the control systems increases the operational availability of Coperion processing plants.