Control solutions for your vacuum sequencing and material loading applications

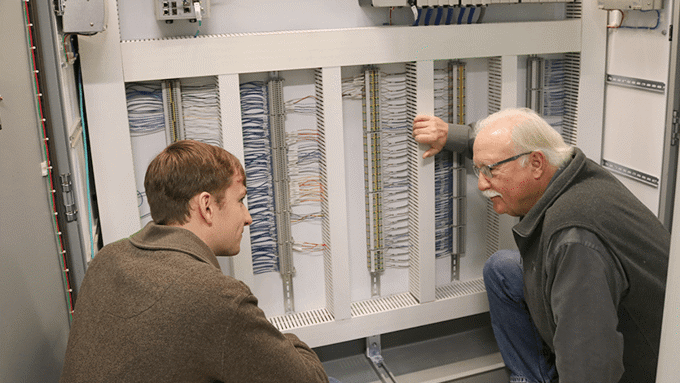

To control the sequence of a Coperion K-Tron multi-component vacuum sequencing system we offer Series 4 Microprocessor (MPC) and Programmable Logic Controller (PLC) controls.

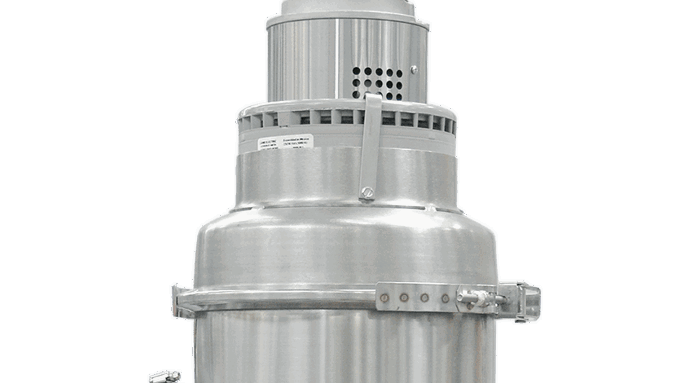

The LSR Controller is available for single central or self-contained units.

Coperion

Open navigation

Coperion

Open navigation