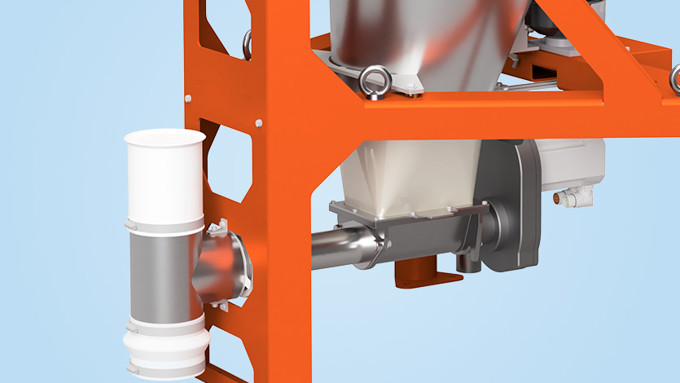

Quick and easy feeding of plastic pellets and granules

Designed for on-machine feeding and mixing, ProRate™ PURE Feeders/Blenders and ProBlend™ Mixers are ideally suited for feeding mixed bulk material in plastics injection or extrusion feeding applications. The volumetric ProRate PURE I and ProRate PURE II feeders can be combined with a simple Gravity Mixer or the more sophisticated ProBlend Mixer for metering an exact and constant material mix into the processing machine. Where higher accuracy is required, the ProRate PURE Blender offers continuous gravimetric blending by adding a scale to each ProRate Feeder.

Little effort is required for adding or removing feeders to and from the process, making this modular system an asset for applications with a variable number of ingredients.