Provides automatic material-from-air separation

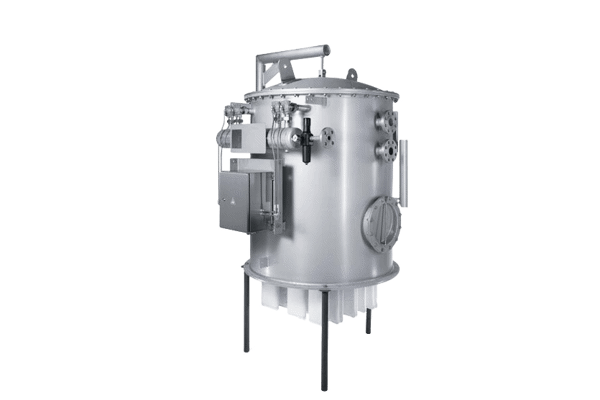

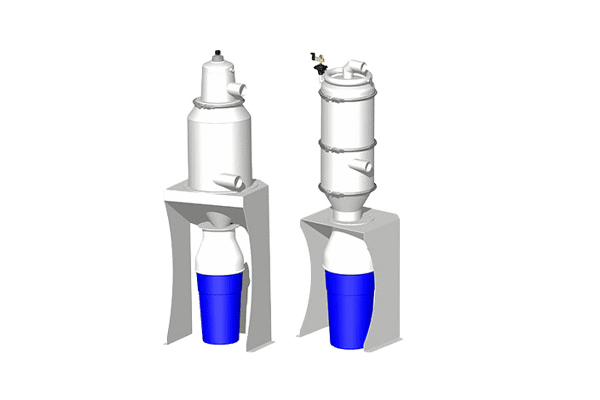

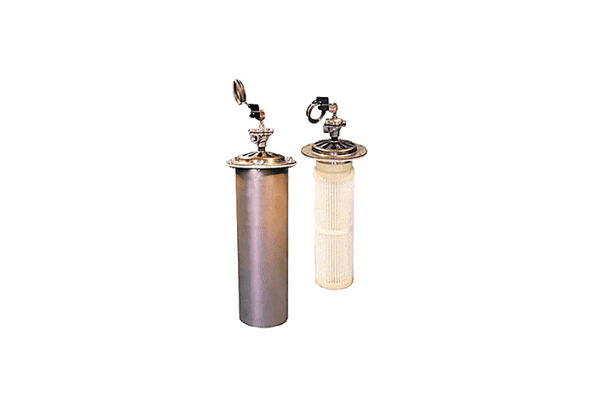

Pulse-Jet Filters provide automatic material-from-air separation. Airborne particles are separated by the filter media. Then sequenced, compressed-air pulses clean the filters, dropping the once airborne material into the hopper or silo.

Efficient performance of the filter is achieved through the proper selection of filter media and the correct sizing. Only the right combination of air-to-cloth ratio and gas velocity assure optimized life-cycle of the filter. Coperion experts are highly trained and can help you determine the correct model of pulse-jet filter for your specific application.