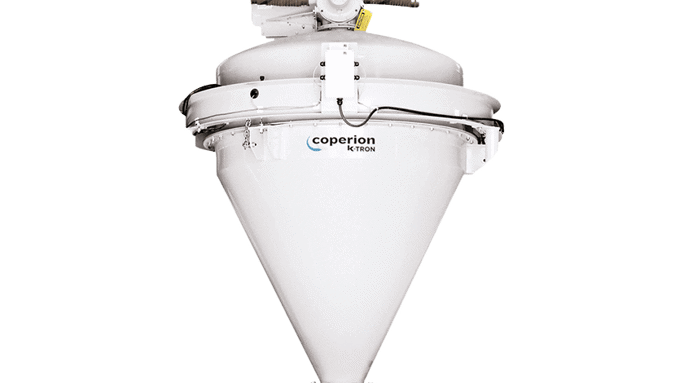

This Sanitary Bag Dump Station with Glovebox is designed to allow bags or small sacks to be opened and dumped into a process in a closed environment. The Bag Dump Station protects the operator from contact with potentially hazardous bulk materials while also protecting the bulk material from conta-mination or interaction with the outside environment. Once inside the hopper, the bulk material is introduced into the process below via a choice of discharge tools – vacuum conveying, screw feeder or discharge valve – depending on the requirements of the bulk material and application.

Function and Operation

The central exhaust ventilation is always on during use to ensure that dust does not exit the unit during loading and/or discharging. The fan is started automatically when the sliding hatch is opened and generates a slight vacuum. Once the hatch is closed the breaker (vent) valve in the exhaust line is activated, blowing a stream of air over the front window to ensure dust does not settle on the window.

The primary filter is only cleaned when the latch is closed and the exhaust fan is on. A protective panel prevents dust from being blown at the front window. The empty bag can be disposed of through a flange at the side of the unit.

If no further bags are emptied within a programmable time frame, the exhaust fan and internal light are automatically shut off. A protective filter between the glovebox and fan prevents dust from exiting he unit in case of damage to the primary filter. A bleeding valve is mounted in the exhaust line for fine adjustment of the vacuum.