Expandable polystyrene (EPS) is a rigid and tough foam. EPS is often used for food packaging, building insulation, and packing material either as solid blocks formed to accommodate the item being protected or as loose-fill pellets cushioning fragile items inside boxes.

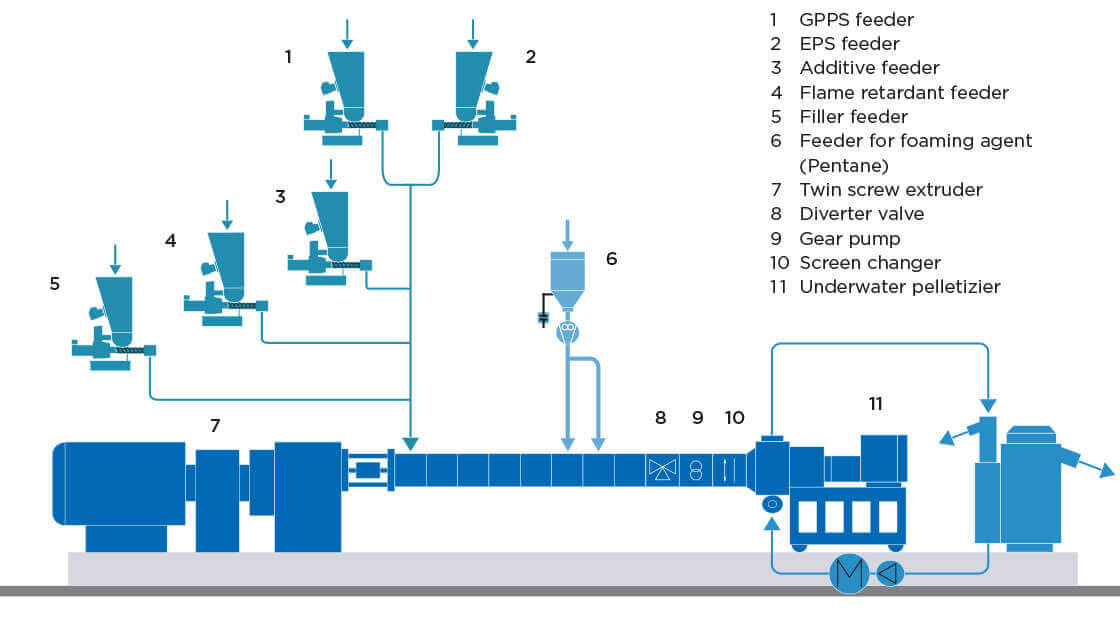

Time-tested, first class Coperion and Coperion K-Tron technology is optimally suited for the single stage production of EPS. Extremely reliable Coperion K-Tron gravimetric feeders provide high feeding accuracy when adding GPPS, EPS, fillers, flame retardants, nucleating agents, color pigments or foaming agents to the process. Due to its intensive mixing behavior and very gentle product handling the ZSK twin screw extruders ensure optimal dispersion of all ingredients. Micropellets are created via an underwater pelletizer and are subsequently expanded or molded.