Circular Economy

A circular economy is an economic system aimed at eliminating waste and the continual use of resources.

Resource Material

Plastic is viewed as a resource material, since significant energy is used in its manufacture (base material petroleum or natural gas) and it can be recycled well. Refuse is presorted, crushed, and then processed into high-value regenerate which is then reused in the plastics industry, closing the loop.

Post-Consumer Waste

Post-consumer waste is waste originating from users, i.e., individual persons, households, and offices.

Post-Industrial Waste

Post-industrial waste is waste material resulting from manufacturing or production.

Chemical Recycling

Using chemical recycling, fossil-based resources can be replaced by material recycled from plastic waste. Using thermochemical processes, plastic waste is transformed and recycled into raw materials, whereby new products with outstanding product characteristics result, based upon recycled plastic waste.

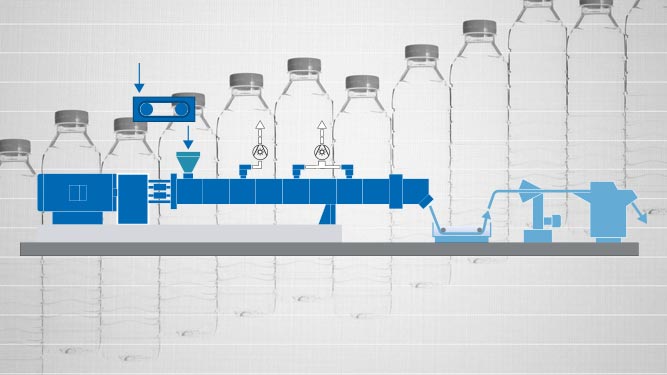

Mechanical Recycling

The term mechanical recycling designates the mechanical processing of used plastics. The chemical structure remains unchanged.

Thermal Utilization

Incineration of plastics; should take place whenever possible in waste incineration plants equipped for this purpose in order to filter out highly toxic substances that are released during incineration, such as dioxins, furans, mercury, cadmium, lead, etc.

Upcycling

Processing of lower-value recyclates, transforming them to higher-value compounds.

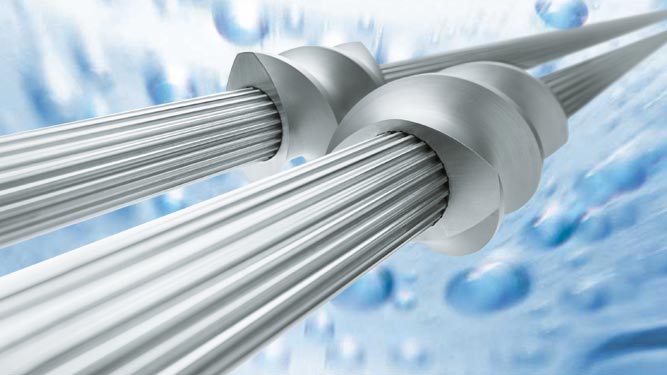

Odor reduction

When recycling plastics, there is often the difficulty that the plastic reused and the recyclates made from it have strong odors. For example, post-consumer plastic waste contains migrated substances from food, cosmetics or cleaning agents. At the same time, residues of monomers, oxidation, hydrolysis and decomposition products can be responsible for the unwanted odors. Odor reduction measures can be taken in various process steps of plastics production and processing. Coperion offers both technologies for degassing during compounding processes and for odor reduction in silos.

Coperion

Open navigation

Coperion

Open navigation