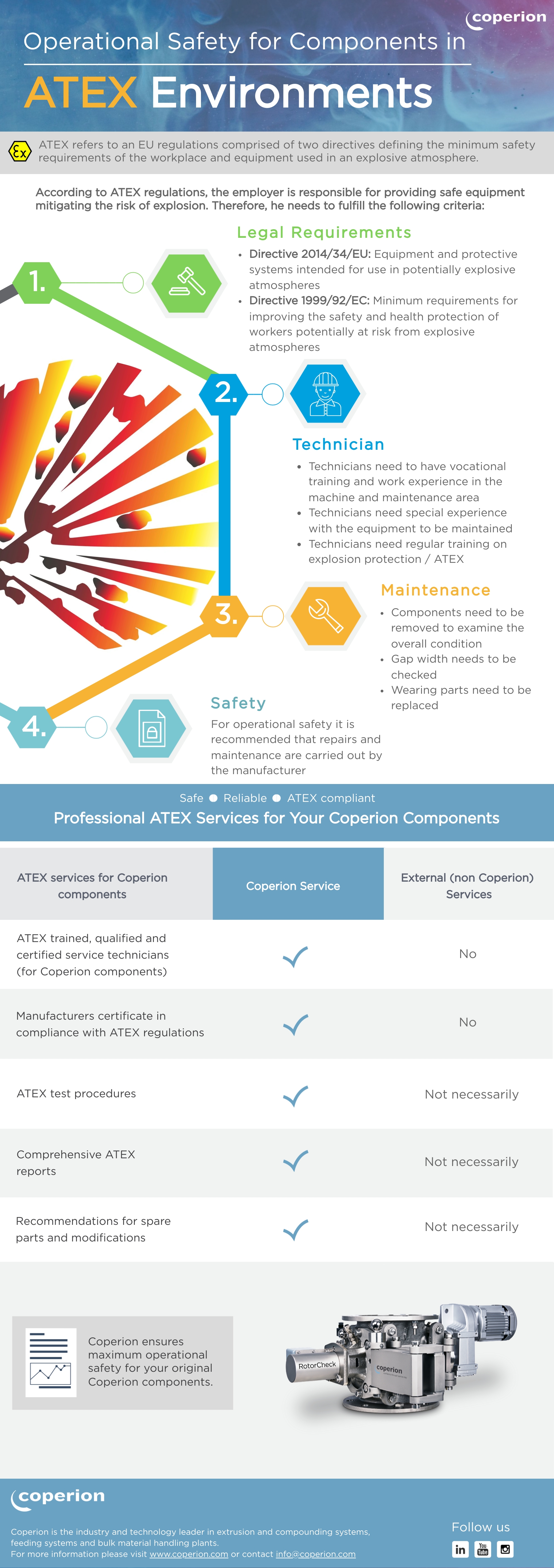

ATEX refers to EU regulations defining the minimum safety requirements of the workplace and the equipment used in a potentially explosive atmosphere (also referred to as hazardous locations).

The regulation is comprised of two directives which dictate the terms of operation. Directive 2014/34/EU sets the minimum standards for equipment and protective systems including safety devices, controlling devices as well as regulating devices. The goal is always to ensure the safe functioning of equipment in order to significantly reduce the risk of explosion. This directive covers all aspects of the design, manufacturing, provision, assembly, use and maintenance of the equipment. Directive 1999/92/EC regulates the safety and health protection standards of workers potentially at risk from explosive atmospheres. This includes among other criteria prevention, risk assessment and documentation.

Coperion and Coperion K-Tron have decades of experience with equipment and components in explosive atmospheres. As a result, safety plays an essential role when it comes to the design of our equipment, whether it be extruders, feeders or components such as rotary or diverter valves. In our Components group, we regularly train companies and offer comprehensive ATEX services to ensure highest possible safety standards. In this context, the proficiency of technicians, the right maintenance as well as operational safety during repairs are a must.

Technicians

Technicians need to have vocational training as well as a good amount of work experiences in connection with the machine and maintenance area. It goes without saying that technicians should also have special experience with the equipment being maintained. This ensures the prevention of fatal mistakes or impairment of the equipment at hand. Further, it is crucial that technicians are regularly trained on explosion protection and therefore the ATEX requirements, to be aware of the relevant details concerning ATEX properties and functions.

Maintenance

During maintenance, all components need to be removed. This allows a thorough examination of their overall condition to detect potential risks at an early stage. In this connection, experts can check several relevant details as e.g., the gap width between housing and rotor, wall thickness of pressure loaded parts, accessories (drive, solenoid valve, etc.). Also wearing parts need to be replaced on a regular basis.

Operational Safety

To enhance the operational safety, it is recommended that both repairs and maintenance are carried out by the manufacturer of the equipment or components.

Therefore, we offer professional ATEX services for all of our Coperion components. Our qualified service technicians are ATEX trained and certified for original Coperion components. We know our equipment inside out and are confident to say that we are able to realize that the highest possible safety levels are met. Hence, we can provide a manufacturer’s certificate in compliance with ATEX regulations that confirms that the equipment fulfils the required properties. Additionally, we work based on professional ATEX test procedures and deliver comprehensive test reports in compliance with the ATEX documentation requirements. Last but not least, our experts can give recommendations regarding spare parts and possible modifications.

Overall, Coperion can help you to achieve a maximum level of operational safety when dealing with ATEX equipment throughout your process.

Download the infographic

Learn more about our services and components

Maintenance & Repair

With our maintenance services we ensure your plant availability and check the efficient utilization of resources.

Service Consulting

From investment in and analysis of existing machines to maintenance and modernization.

First-class rotary valves

Our rotary valves are highly regarded as top-quality products in the plastics, chemical, food and minerals industries around the world.

Coperion

Open navigation

Coperion

Open navigation