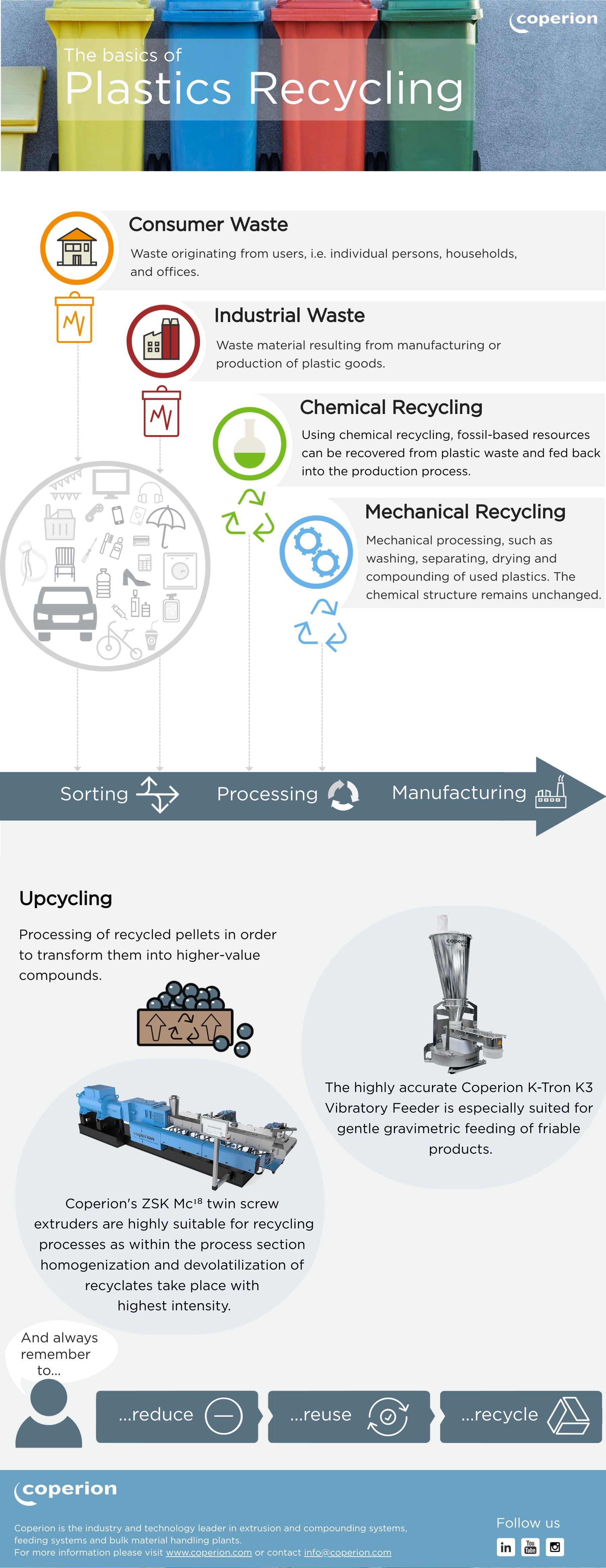

For this reason, it is essential to create a so-called Circular Economy in the long run. This concept is based on the approach of “reduce, reuse and recycle” and pursues the objective to feed plastic waste back into the value chain to produce new plastic. Although recycling is a key element of the Circular Economy, it is a fairly complex process. Get an idea of some of the basics of plastics recycling in the following infographic:

As the infographic shows, there are generally two types of plastic waste – household and industrial waste. While household waste is attributed to individual persons, households or offices, industrial waste results from the manufacturing of products. Before any kind of plastic waste can be recycled, it needs to be sorted first. Purity plays a major role when it comes to the quality of recycled material.

After the initial sorting, the material can then be further processed. There are various forms of recycling processes with different objectives. Two of the most common approaches are chemical and mechanical recycling. The idea of chemical recycling is to recover fossil resources from recycled plastic and feed them back into the production process. The term mechanical recycling on the other hand refers to the washing, separating, drying and compounding of used plastic. The chemical structure remains the same.

One important concept in regard to plastics recycling is upcycling. It describes the process of transforming recycled material into higher value compounds. To achieve this, recycling companies need to select suitable equipment which provides high quality material. Since recycled material is known for being heterogeneous in size, form, bulk density and therefore is difficult to handle, it is important to pick a feeding system that takes these special requirements into account. The newly developed K3 vibratory feeder from Coperion K-Tron is characterized by its high accuracy and is especially gentle to the material. Based on its high precision and efficient process control, the K3 vibratory feeder is able to handle fluctuating bulk density well. For this reason, it is extremely suitable for recycling processes.

In terms of compounding and the actual upcycling process, twin screw extruders have proven to achieve the best results due to the high dispersion and devolatilization of the material. Coperion’s ZSK twin screw extruders are used for high performance applications and are hence well-suited for manufacturing high-quality recycling compounds.

Download the infographic

Learn more about Coperion's Plastics Recycling Solutions

Plastics Recycling

Discover comprehensive technology solutions for plastics recycling.

Recycling Solutions Video

In this short video Coperion's recycling experts give an overview over our recycling solutions.

Recycling Whitepaper

Get more in-depth information on plastics recycling in our latest recycling whitepaper.

Coperion

Open navigation

Coperion

Open navigation