Many developments in recent decades have focused primarily on improving the process quality, reliability and throughput of extrusion and compounding lines. In the meantime, the reduction of energy consumption and thus more sustainable operation have been added as very important quality features of extrusion and compounding lines. Both topics have been the focus of our research and development work for several years now. Our goal is to ensure that Coperion extruders reliably deliver the highest product quality at very high throughput rates in the long term and that the amount of energy required for this is as low as possible.

If we take a closer look at the extrusion process, there are numerous factors to consider that influence both the compound quality, the throughput and the energy consumption of an extrusion line. With many years of experience and comprehensive know-how for the entire manufacturing process, our experts examine all parameters and put together an individual package of worthwhile modernization measures for each system. Every manufacturing process and extrusion line offers a wide variety of possibilities for reducing energy consumption and thus making their operation more environmentally friendly. In all the modernizations we have carried out on Coperion extruders to date, energy savings of between 8% and 14% have been achieved on average.

Potential for an Improved Energy Balance

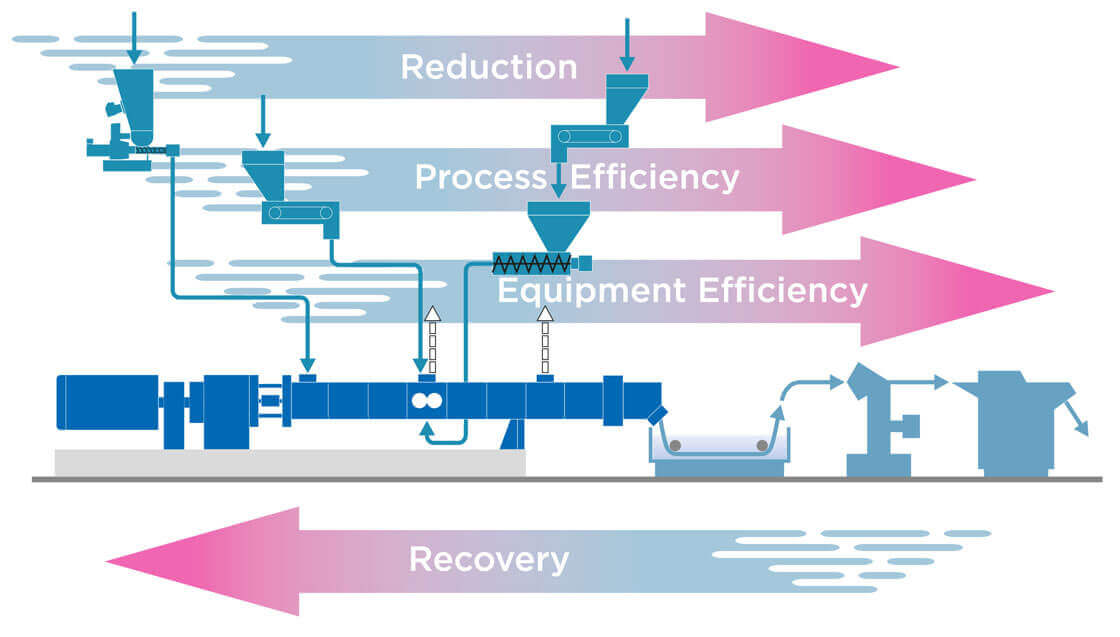

Our experts pursue different approaches to optimize the energy balance of an extrusion system. In many cases, modernization of the extruder drive already leads to significantly better utilization of the energy input and thus to a reduction in energy consumption. In addition, each individual process step in production and their interrelationships can provide potential for reducing energy consumption. For example, it is possible to recover energy from the pelletizing water and return it to the production process to melt raw materials. For this purpose, Coperion uses specially developed heat exchangers that are designed for the respective process. Even on the process section of an extruder, changes to the heating of the barrels or their insulation can provide optimizations in energy consumption. In addition, adjusting the screw configuration can reduce energy input.

When determining the potential for a better energy balance, our experts consider the extruder itself and the material transfer, feeding and pelletizing systems. Coperion has the process know-how for the entire manufacturing process and, as a long-standing technology supplier, has detailed insights into the functioning of all components and their interrelationships.

This makes us the ideal partner for identifying potential energy savings in extrusion and compounding systems. Contact us!

Coperion

Open navigation

Coperion

Open navigation