Due to their relatively low up-front costs, batch weighing systems are a common production setup in many industries. In addition to improving product quality over traditional manual batch weighing methods, automation of the material handling, product transfer, and batch weighing processes can greatly increase overall efficiency. Properly weighing and accurately delivering the ingredients without manual intervention can result in several process advantages, including overall safety, fewer mistakes, better accuracy, lower bulk material costs, improved product quality, and savings in manufacturing costs.

When considering an automated batch weighing system, it’s important to look at several factors that will influence the type of batching system recommended and optimize ingredient cost savings and overall return on investment (ROI). The main considerations include deciding between a gain-in-weight (GIW) or loss-in-weight (LIW) system, deciding between volumetric or gravimetric feeders for batch accuracy, determining your desired batch times, knowing the number of ingredients and their characteristics, and knowing the space limitations.

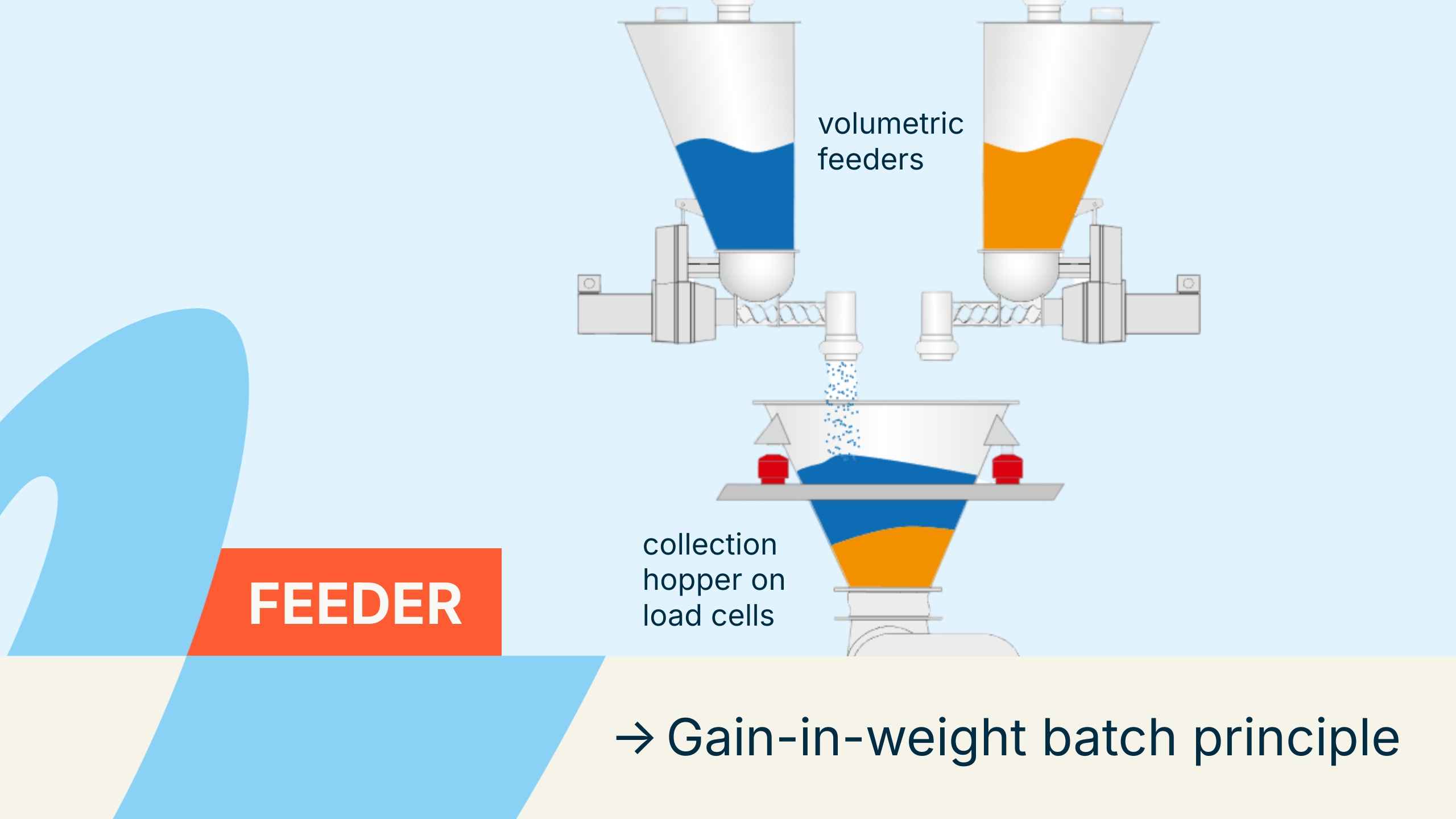

Gain-in-Weight Batching Principle

In GIW batching volumetric feeders sequentially feed multiple ingredients into a collection hopper mounted on load cells. Each feeder delivers approximately 90% of the ingredient weight at high speed, slowing down towards the end of the cycle to deliver the last 10% at a reduced rate to ensure higher accuracy. The GIW controller monitors the weight of each ingredient and signals each volumetric feeder to start, increase or reduce speed, or stop accordingly. Once all the ingredients have been delivered, the batch is complete and the mixture is discharged into the process below. It should be noted that this type of batching method is sequential for each ingredient, and therefore generally results in a longer overall batching time than with LIW batching (outlined below) if the number of ingredients is high.

For further illustration of the actual GIW batch process watch the following video:

Coperion

Open navigation

Coperion

Open navigation