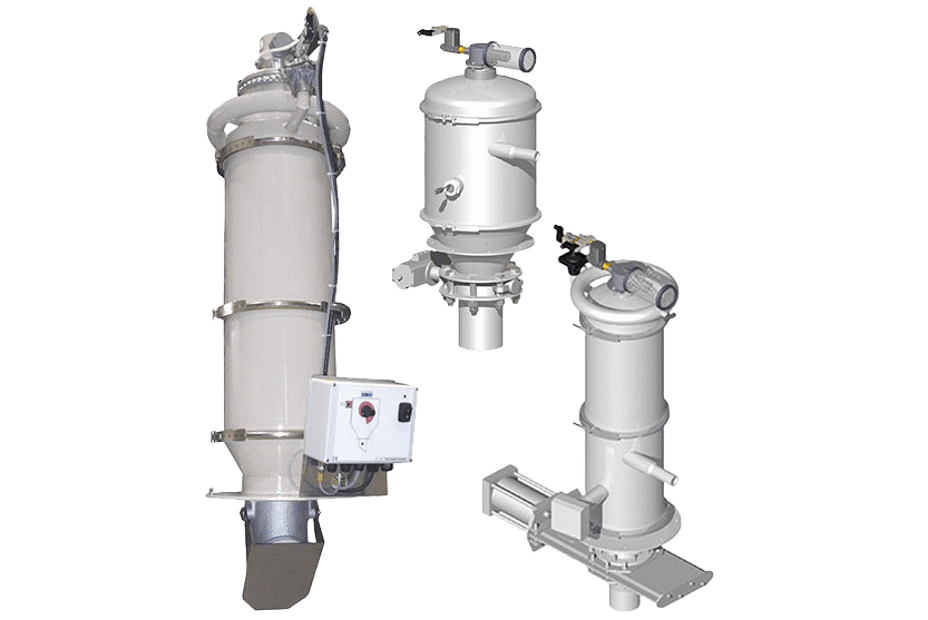

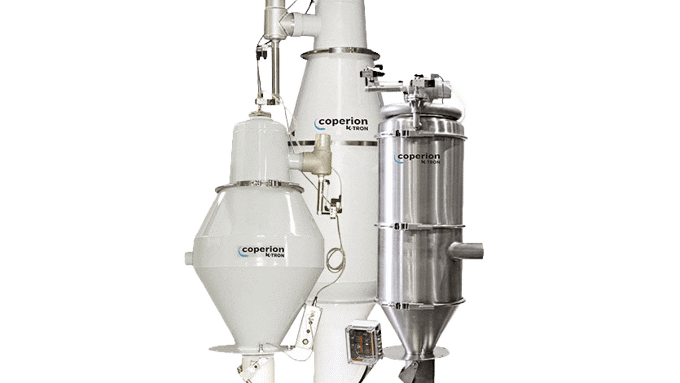

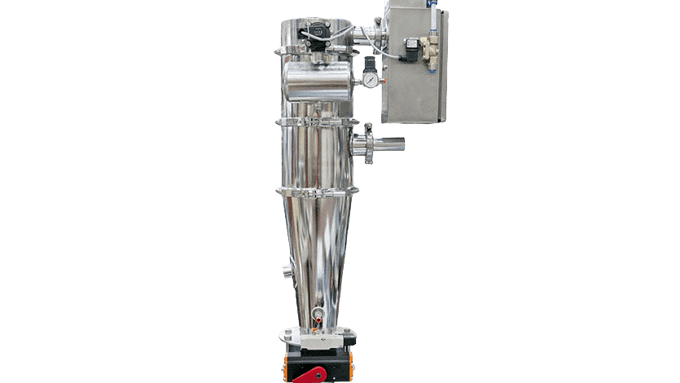

Self-contained machine loaders & venturi style loaders

Coperion K-Tron self-contained loaders are compact, economical and efficiently handle pellets as well as regrind or granular materials. The self-contained loaders come with a power head mounted on top of the unit and controller. They are most commonly used for machine loading and other applications where material is moved short distances and to one destination.

Coperion K-Tron venturi loaders are designed to move bulk material with compressed air as the vacuum source. They include a controller and venturi vacuum pump.

Coperion

Open navigation

Coperion

Open navigation